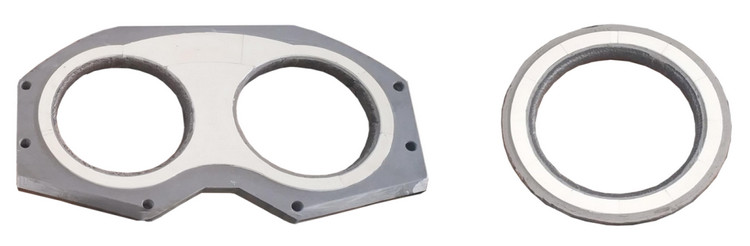

Wear-abrasion problem is a headache for concrete pumping systems in infrastructure construction such as road, bridge, building, tunnel, railway etc. Due to a high and continuous working pressure, the wear plate and the cutting ring are easily worn-out which finally lead to a frequent maintenance and lower working efficiency for the concrete conveying systems.

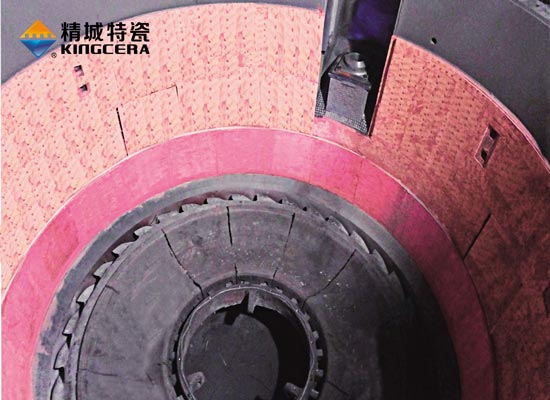

Recently, one Russian customer turned to KINCGERA for help as they want to guarantee a more stable and continuous working status for their PUTZMEISTER Concrete Pumps. In the past, they have been using the Tungsten Carbide wear plates, but the result is not as good as their expected in today’s competive market. They hope to apply a new kind of wear plate with longer service life in their machines. After a deep communication with the customer, we get to know the site working conditions:

Concrete B25

Crushed stone on granite

Fraction 5*20mm

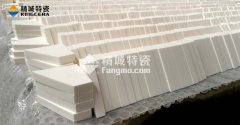

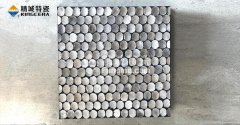

When carefully considering the working conditions, KINGCERA provided the solution of super wear-resistant ceramic wear plate sets for our customer. This wear plate consists of overlay-welding and ARZ ceramic, which combines the best mechanical property of these two type material. Of cause, this will provide a long-last and stable service life time and reduce down the whole cost. Now the ceramic wear plate has been installed in their machine and keeps working successfully.