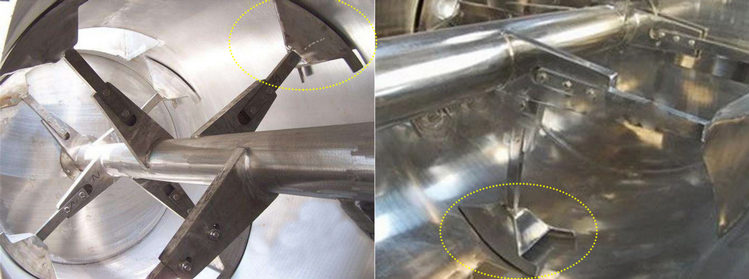

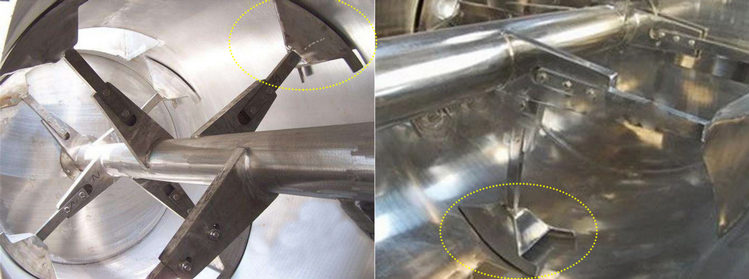

Horizontal coulter mixer plays a very important role in the fine powder granule. Usually the machine composes of transmission structure, horizontal type drum, coulter and blades. The materials flow forwards in axial direction along the drum shell by the force from the coulter driven by high speed rotation in order to get fine and evenly mixed powder in a short time.

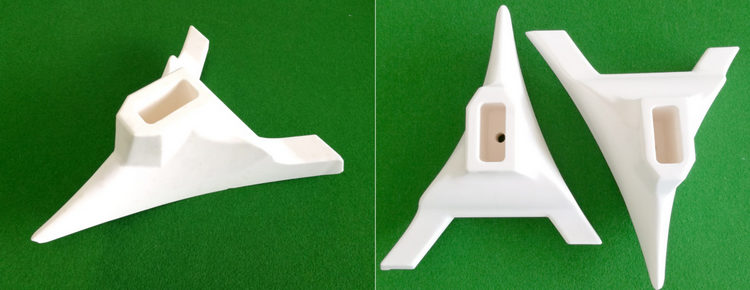

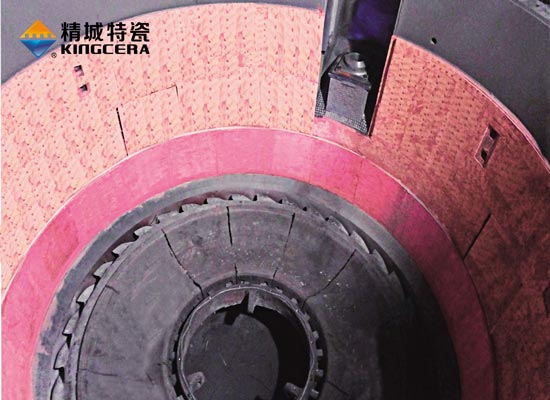

However, under a continuous working status, the steel coulters are suffered from serious abrasion and wear problems, then the mixing efficiency will gradually become lower and lower. In order to solve such headache problems, KINGCERA invented the super-wear-resistant ceramic coulter to replace the steel coulter. From the State Key Laboratory for Powder Metallurgy lab test, the wear resistant performance of ceramic is 266 times than manganese steel and 171.5 times than the high-chrome cast iron. Definitely, KINGCERA’s super-wear-resistant ceramic coulter will crease the whole service lifespan for the horizontal coulter mixer to a new record.