Description:2023 is an important year for the construction and production expansion of KINGCERA,and the addition of 5 large ceramic ball mills is an important part of it. KINGCERA adheres to the one-stop model production, from the most basic powder calcining and grinding to the later installation and maintenance, every link is strictly controlled. The appearance of the 5-ton ball mill directly improves the preparation efficiency of powder, increases production and reduces consumption, and realizes powder making The craft is upgraded again.

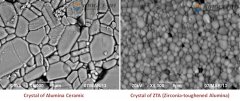

KINGCERA has always insisted on selecting high-quality bauxite and converting it into α-alumina through high-temperature calcination. Calcined alumina powder does not have a single crystal, but agglomerates multiple powder particles. In order to obtain ceramic materials with different properties, it is necessary to process the powder according to the formula, that is, powder grinding: there are many methods for material grinding, KINGCERA adopts the grinding method of wet ball mill and stirring mill, and the ball mill is an important grinding method tool.

The 5-ton ball mill powder line in the expansion of KINGCERA

Today, 50 sets of 500kg ball mills have been put into production in KINGCERA , and another 50 sets of 500kg ball mills are being prepared for installation. However, this type of ball mill is mainly aimed at refined products. The 5-ton ball mill purchased this time can make the grinding of powder in batches, and improve the efficiency of powder making while ensuring the quality of powder. In addition, the 5-ton ball mill has a stronger grinding capacity, and the ground powder has a uniform particle size and is more rounded, and the performance of the sintered alumina ceramic products is also more stable and balanced.

The one-stop production model makes KINGCERA's various production links complement each other and become an organic whole. The 60-meter atmospheric kiln has greatly increased KINGCERA's ceramic output, but this also requires simultaneous improvements in the speed of and the powder press preparation forming green bodies. Therefore, KINGCERA is ushering in a comprehensive industrial upgrade. Not only is it more refined and better in high-end products, but it will also cover a wider range of ordinary products, which can better meet the needs of customers ,also provide to customers with more comprehensive and excellent service!