Product Introduction

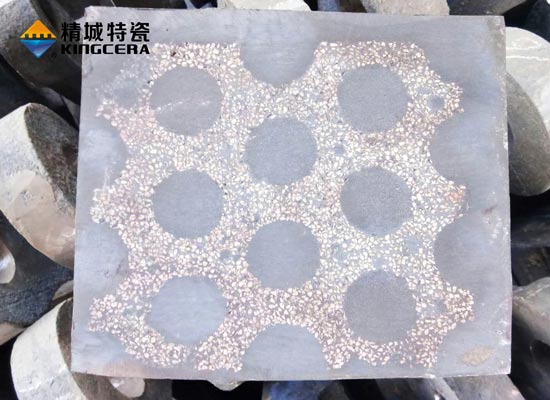

MMC metal matrix composite: combine high-hardness and high wear-resistant ceramic grain with metal materials, form a certain thickness MMC layer on wear parts’ working face. The composite layer is used to bear wear and the metal matrix plays a bearing role. This compounding method can not only improve the wear resistance, but also ensure its overall toughness.

The metal matrix supports the reinforcing grains and must have a certain strength and toughness. It is mainly a variety of wear-resistant cast iron and alloy steel. The appropriate matrix should be selected according to the specific working conditions of the composite material. Ceramic particles are the main wear-resistant phase in composite materials. ZTA ceramic grain must have a higher hardness than the matrix, then could effectively protect. Furthermore, the ceramic grain must have good interface bonding properties with the matrix to ensure that they will not fall off during service.

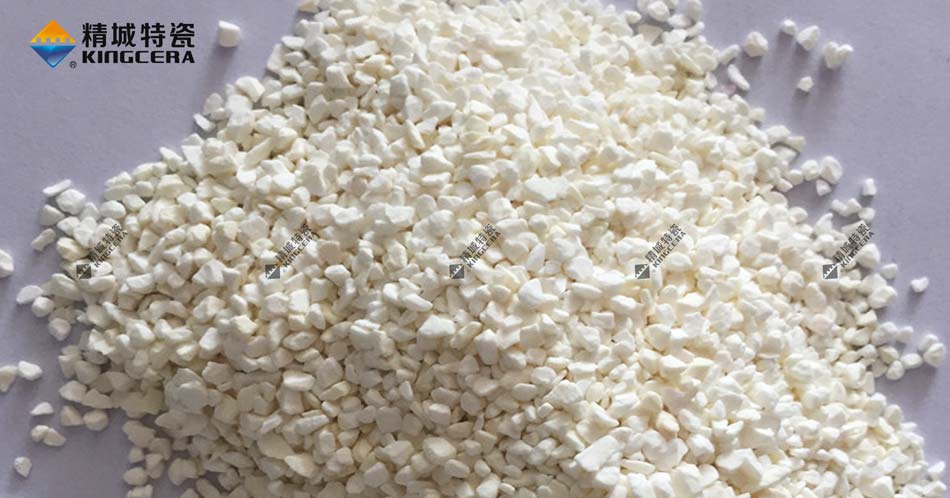

Commonly used grain materials in MMC wear parts are WC, TiC, Al2O3, ZTA (zirconia toughened alumina). WC and TiC grains are too expensive and the industrial production cost is too high. The toughness of Al2O3 ceramic grain is too poor, and it is easy to break by itself under impact conditions. In contrast, ZTA ceramic grain have great advantages in hardness, toughness and cost, and are now widely used in MMC square hammers, plate hammers, swing hammers, grinding rollers and other products.

After countless formulation optimizations and process improvements, the ZTA wear-resistant ceramic particle produced by Hunan Kingcera have high hardness, good impact resistance, good wear resistance, controllable particle size, uniform particle size distribution, and particle shape. Good appearance, good wettability with the metal matrix, etc., is the first choice for the preparation of MMC wear parts.

Product Display