In the preparation process of lithium battery materials, the powder classification stage imposes extremely high requirements on equipment wear resistance, operational stability, and metal isolation capabilities. Leveraging advanced ceramic material technologies and precision manufacturing processes, Kingcera provided a customized high-performance ceramic grader solution for a renowned lithium battery enterprise in Jiangxi, earning the client's long-term trust and repeated orders through exceptional wear resistance, stable operational precision, and professional support services.

I. Integrally Molded Grader: The Durable Choice for High-Speed Operating Conditions

Addressing the application environment of the client's jet mill powder equipment, characterized by high speeds (up to 6000 RPM) and significant abrasion, Kingcera offers the integrally molded K99 ceramic grader. This product utilizes an integral molding process with a maximum diameter of up to 315 mm, balancing structural strength with operational stability to effectively achieve wear protection and metal isolation during high-speed rotation.

To ensure stable operation at high speeds, each grader is accompanied by a dynamic balancing inspection report and a CMM (Coordinate Measuring Machine) precision inspection report, guaranteeing geometric accuracy and smooth operation from the source of manufacturing to meet the lithium battery industry's stringent requirements for equipment stability and product purity.

Split-Type Ceramic-Lined Grader

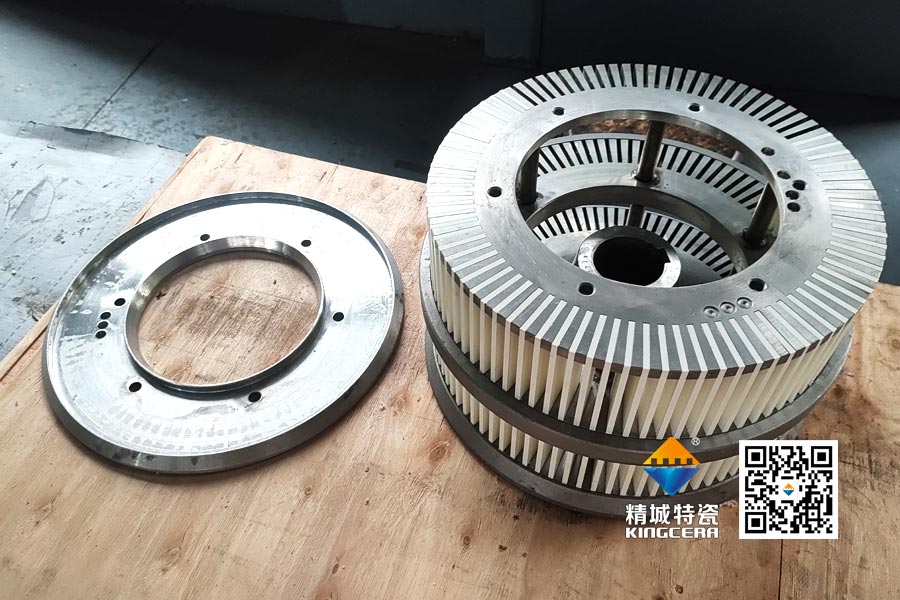

II. Split-Type Ceramic-Lined Grader: High-Precision Adaptation and Excellent Performance

For lithium battery powder classification equipment requiring even higher speeds (8000 RPM), Kingcera has introduced the split-type ceramic-lined grader. Utilizing ARZ ceramic tiles that undergo precision grinding, this solution achieves excellent bonding and adaptation with the metal substrate; the overall assembly effect balances the wear resistance of ceramics with the load-bearing strength of the metal structure.

After three months of continuous operation at the client's site, the ceramic tiles remained in pristine condition with no visible signs of wear on the surface. Client feedback has confirmed the reliability and durability of the product under long-term high-frequency operation, fully satisfying the core requirements for low wear and high stability in lithium battery material production.

As ceramic grader are high-precision and fragile components, the Kingcera business team insists on dedicated personnel for direct delivery to ensure the product arrives intact, earning high recognition from the client for this highly responsible service attitude. Thanks to superior product performance and dedicated service, the client placed three consecutive repeat orders within six months, establishing a stable supply chain partnership.

Kingcera remains committed to providing customized processing solutions for high-performance ceramic components in fields such as lithium batteries, new materials, and chemical engineering. We persist in letting measured data speak, supported by professional inspection reports and driven by authentic client feedback, to continuously optimize product design and manufacturing processes, helping clients improve equipment efficiency, extend service life, and guarantee product purity.

(Original link:

精城特瓷陶瓷分级轮:为锂电粉体高效分级提供可靠解决方案 )

Samuel Wu / Translated