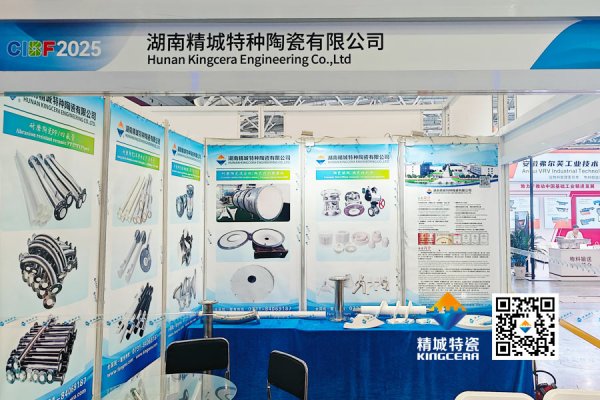

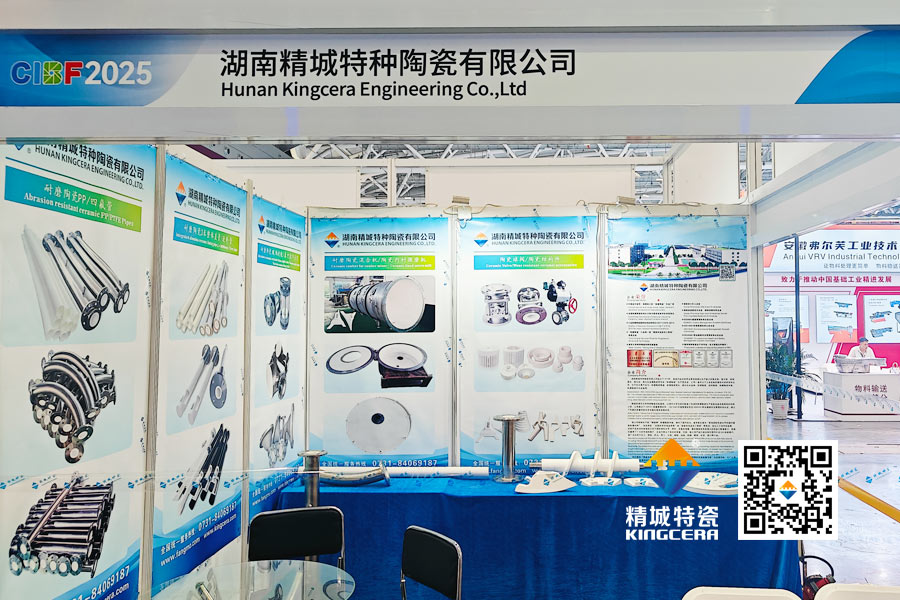

The 2025 Shenzhen International Lithium Battery Technology Exhibition (CIBF) was held at the Futian Convention and Exhibition Center from May 15 to 17. As a global benchmark for the lithium battery industry, this event brought together cutting-edge technologies and solutions from across the supply chain. KINGCERA showcased its independently developed high-performance ceramic-lined pipes, offering superior wear resistance, corrosion resistance, and long-term stability to provide safer, more economical, and longer-lasting solutions for material handling in lithium battery production.

Why Do Lithium Battery Companies Need KINGCERA’s Ceramic-Lined Pipes?

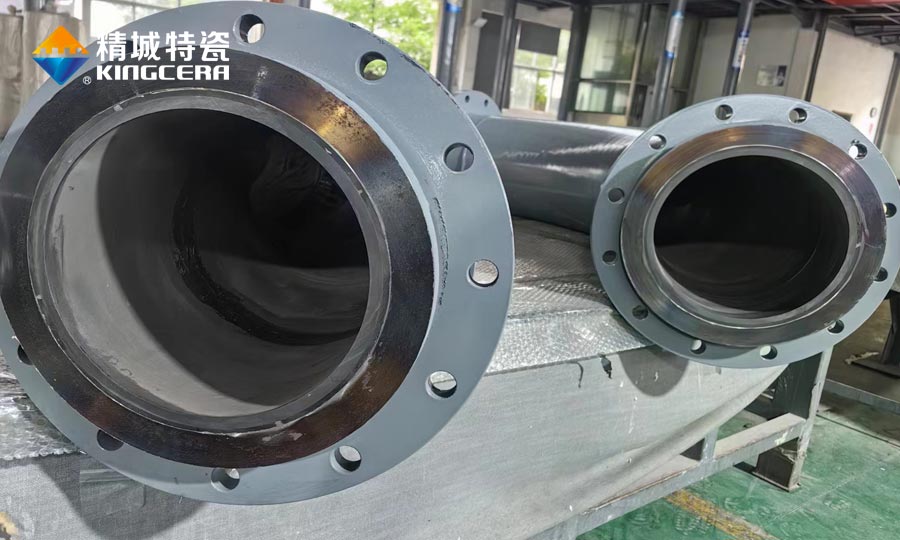

In lithium battery production, the transportation of raw materials such as cathode/anode materials and electrolytes demands extremely high wear and chemical corrosion resistance from pipelines. Traditional metal pipes wear out quickly and have a short lifespan, requiring frequent replacements that increase costs and may introduce impurities, affecting battery consistency. KINGCERA’s ceramic-lined pipes stand out as the ideal choice for lithium battery manufacturers with three core advantages:

-Exceptional Wear Resistance, Extending Lifespan by 10x+

Featuring a high-purity alumina ceramic lining with a hardness of HRA90+, the ceramic lining pipes far surpass ordinary steel pipes in wear resistance. They effortlessly withstand the high-speed abrasion of lithium battery powder materials, significantly reducing replacement frequency and downtime maintenance costs.

-Corrosion Resistance, Ensuring Material Purity

The chemically stable ceramic layer resists acid and alkali corrosion, preventing metal ion contamination and safeguarding the purity of battery materials. This enhances battery consistency and safety.

-Lightweight Design, Easy Installation

The composite structure reduces weight by 30% compared to traditional ceramic pipes while maintaining high strength, facilitating on-site installation and layout optimization to meet the efficiency demands of lithium battery production lines.

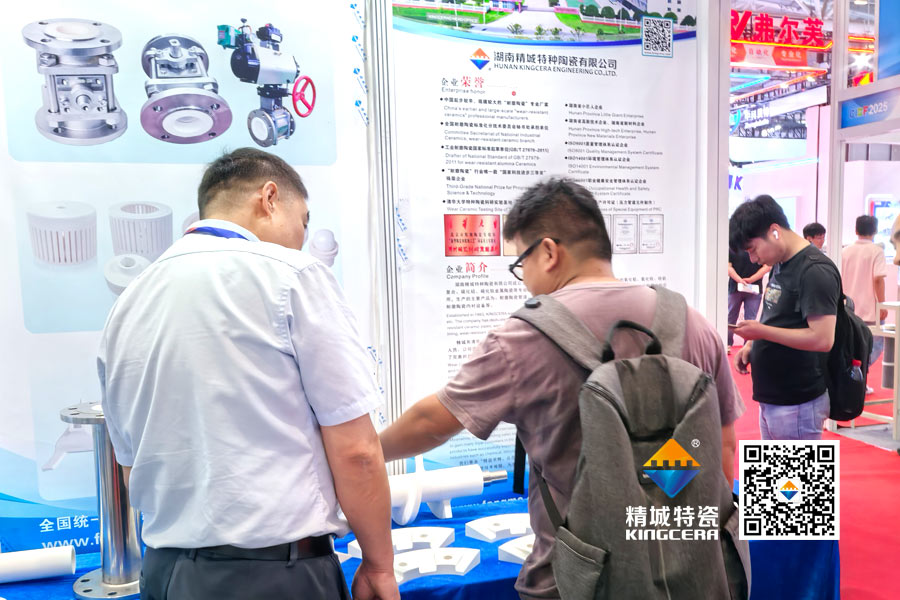

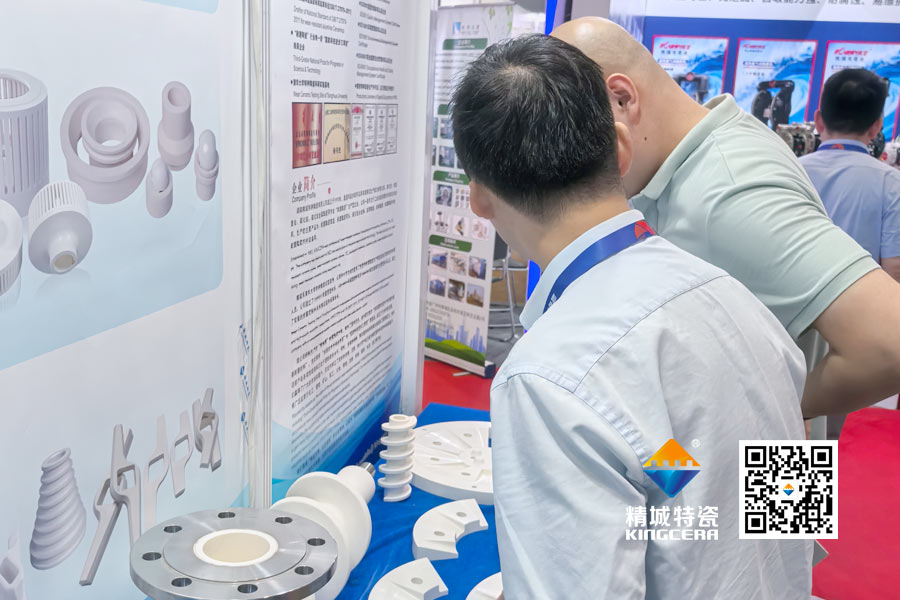

A Fruitful Exhibition for KINGCERA

At this exhibition, we engaged in in-depth discussions with numerous partners across the lithium battery supply chain, exploring innovative applications and future trends of ceramic-lined pipes in lithium battery production. We extend our gratitude to every industry professional who visited the KINGCERA booth—your attention and recognition drive us forward!

With over 30 years of expertise in industrial ceramics, KINGCERA’s products are widely used in new energy, metallurgy, chemicals, mining, and other industries. Moving forward, we will continue to focus on material innovation, delivering high-quality and high-performance products to provide more efficient and durable solutions for the lithium battery industry. Our goal is to help clients reduce costs, improve efficiency, and drive industrial advancement.

Steven He