Kingcera Engineering is a globally

wear resistant ceramic manufacturer in design, production, installation and services.

The wear problem are always a headache for many industries in the process of materials. It wear problem can damage the equipment, reduce the production capacity, increase the maintenance cost, as well as polluted environment. Kingcera’s ceramic wear liner is a durable solution for a wide range of corrosion and wear protection applications.

According to different working conditions, the different ceramic lining will be recommended.

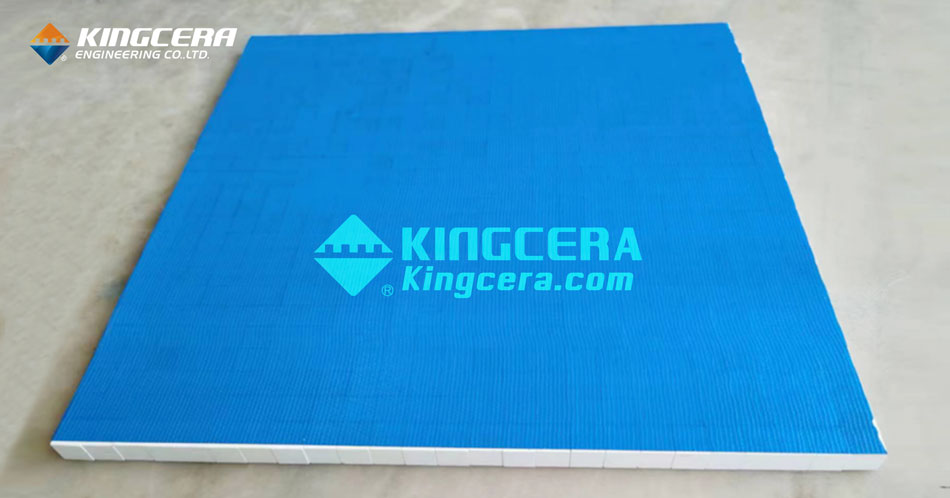

1.Direct ceramic tile lining

The ceramic tile lining is usually make into a ceramic sheet by a glue paper. This lining is suitable for the non-severe wear applications.

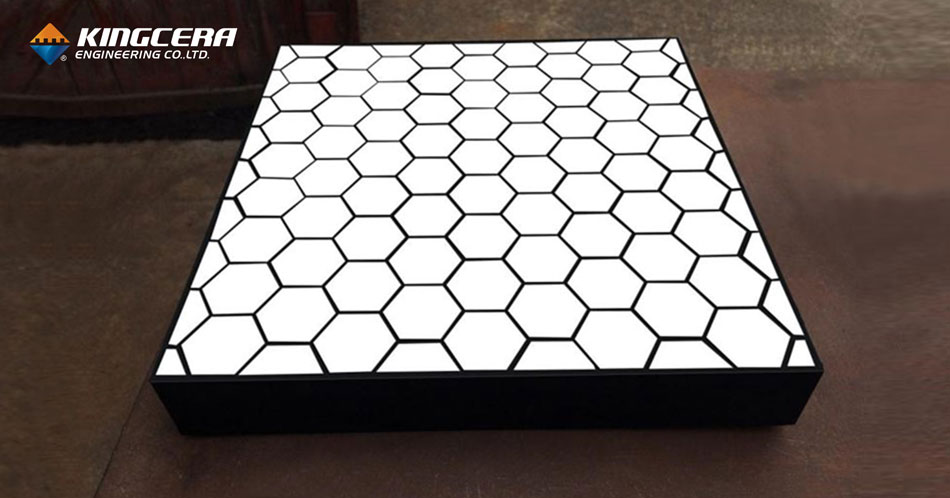

2.Ceramic rubber wear liner

Ceramic Wear liners comprise of alumina ceramic tiles, molded in a high tensile strength natural rubber matrix, and mounted on steel backing plates. All rubber ceramic liners are hot vulcanized together using specialized equipment which provides a bond strength that exceeds the tensile strength of the natural rubber matrix. As a result the ceramics will remain in the rubber matrix, offering consistent wear protection across the entire life of the liner.

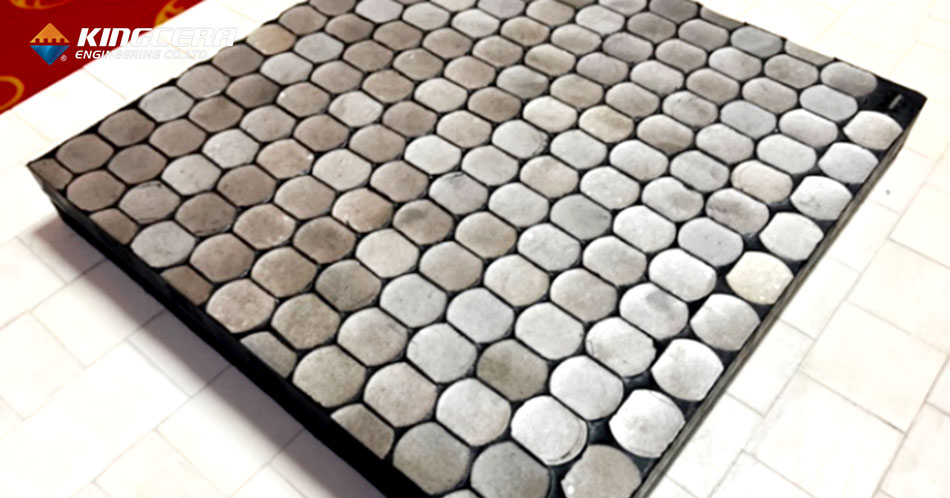

3.Titanium carbide and rubber wear liner

Tic wear liners comprise of Tic insert, moulded in a high tensile strength natural rubber matrix, and mounted on steel backing plates.

Tic wear liners are designed for maximum resistance to impact and abrasion for use in many bulk materials handing applications. With specific focus on maximum abrasive resistance for Iron Ore and other hard rock applications.

4. Silicon Carbide and Rubber wear liner

Silicon Carbide wear liners comprise of Silicon carbide ceramic, moulded in a high tensile strength natural rubber matrix, and mounted on steel backing plates.

The silicon carbide ceramic liner is specially designed for severe slide wear and big volume wear application. The Silicon carbide has very high hardness, up to 2300 Vicker Hardness. So it is good for the slide wear but not suitable for the impact wear.