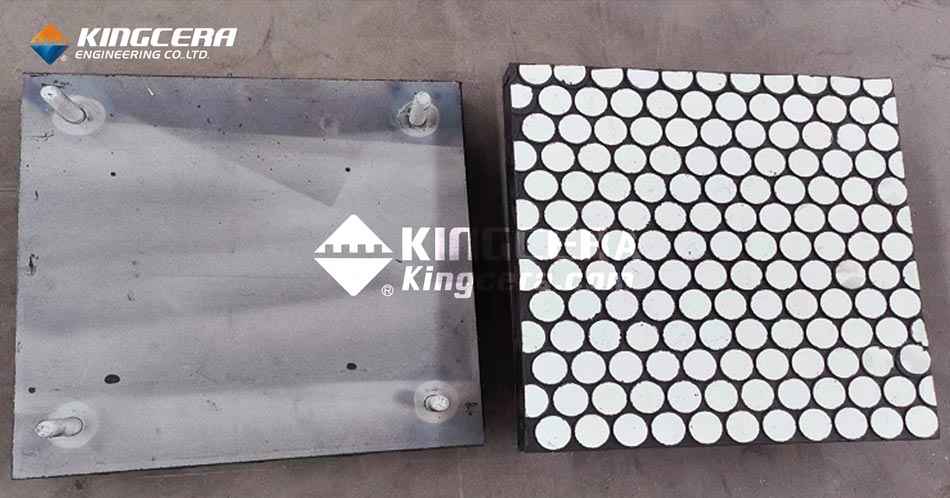

Kingcera’ ceramic wear steel plate are composite together by vulcanizing with the ceramic, rubber and steel plate, connected with the studs and nuts. It's one of the perfect products for the wear&impact protections applied in the chutes,hoppers and deflectors for the mining, cement, steel and power plant.

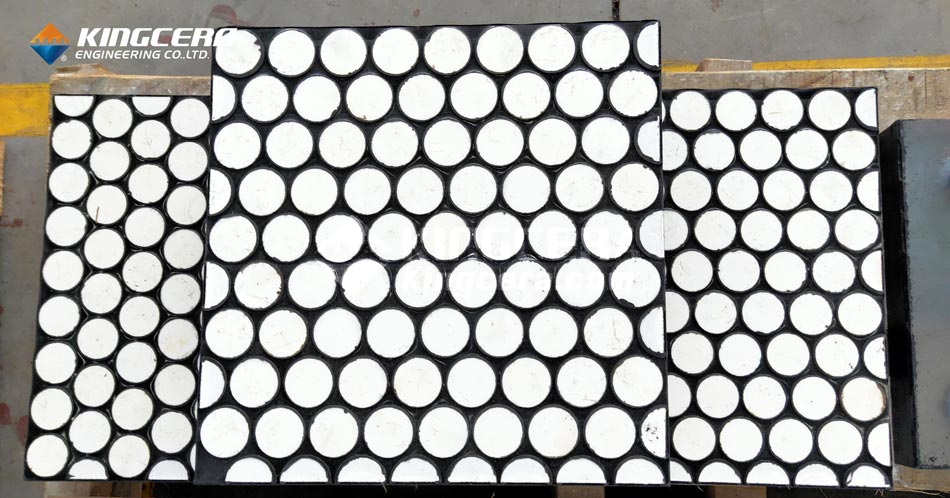

Kingcera have a wide ranges of the ceramic type options which can meet different applications according to the different working conditions. We have rectangle,square,round,triangle and hexagonal shape of the ceramics. But Today,I’d like to introduce our cylinder ceramic type for the ceramic wear plates.

The cylinder ceramic are pressed as a small round type before sintering.We will check the products quality,sizes and spray the vulcanizing adhesive to the cylinder surface before the liners vulcanization by rubber and steel plates. As a result, the ceramic wear plates will not only remain in the rubber’s impact ability, but offering consistent wear protection across the entire life of the liner.W e will also follow the customer’s requirements to decide whether we should weld the studs or not .

What’s more,besides the different ceramic shapes,Kingcera can not only provide the 92%,95% and 99% alumina material for the different wear serious spot, but the ZTA,ARZ and pure zirconia for the high wear&impact position since the medium size is bigger and falling height is high.