Introduction: Nothing is always smooth sailing, we always grow from failure. Here it will use a successful case of ceramic liner installation in vertical mill barrel, to illustrate our company’s turning point of career.

Vertical mill is ideal large-scale pulverizing equipment, which is widely used in cement, electric power, metallurgy, non-metallic ore and other industries. It can crush, dry, pulverize and graded convey with high efficiently. What’s more, it can grind lumpy, granular and powder raw materials into required powder materials.

As large-scale pulverizing equipment, vertical mill stands out for its energy-saving advantage and high efficiency. However, the downtime caused by the wear of internal parts of vertical mills increases the cost of production, and increasing the lives of the easily worn parts in vertical mill has become the most important issue for the personnel in charge of equipment in enterprises.

At present, ceramic and metal composite materials have been used for vertical grinding rollers and grinding disks, for the vertical grinding is easy to wear due to the internal erosion caused by high temperature and high concentration of dust. For instance, in a wear-protection project of August, 2012 of ours, it is required to give 12 vertical grinding cylinder

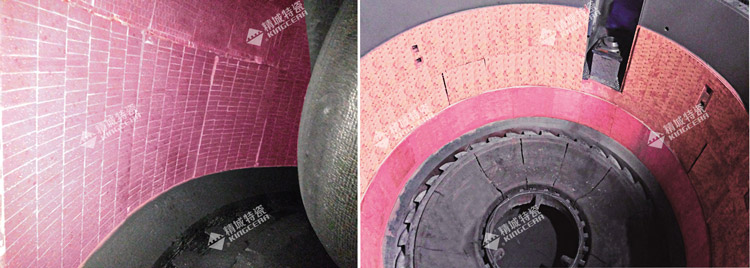

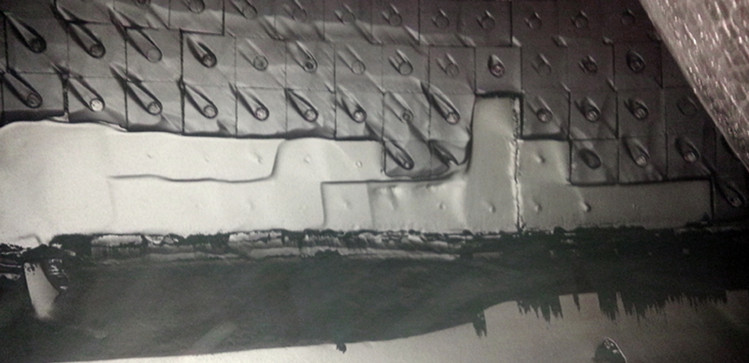

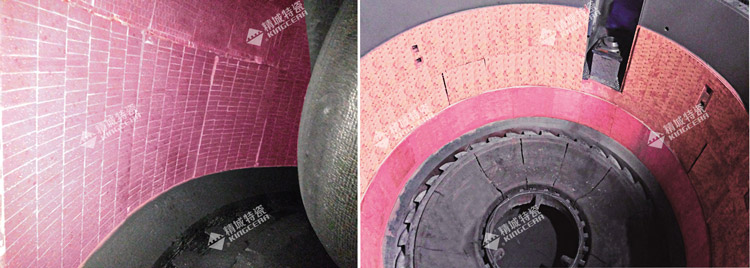

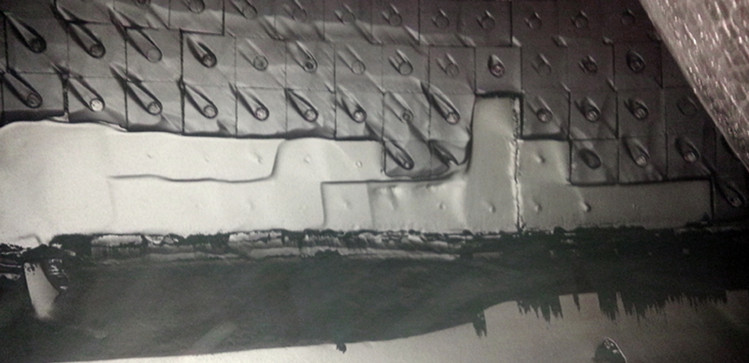

wear resistant ceramic protections. The original plan is to weld 15 mm wear-resistant ceramics (central perforated) within the cylinder walls. After 30 days of work, it turned out that ceramic dropped from the static ring areas in the vertical mill. The closer it is to the air guide ring, the higher the temperature is, the greater the impact of material erosion, and a serious sunken of wind erosion is made at the welding nail.

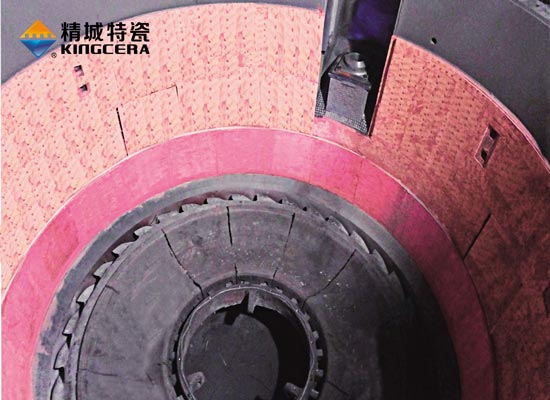

According to the field investigation and analysis of our technicians, the wear resistant ceramic and steel composite lining plate with dovetail guide rail technology was adopted to make the surface of the lining plate smooth and impact resistant. After days of repair regardless of the cost, we finally solved this severe problem. Now the service of this equipment has been working for more than 6 years. Since then, we have been focusing on developing new products to solve the problem of wear and erosion and make many excellent achievements.

At present, there are many manufacturers and brands of vertical mills from home and abroad. Foreign representative mill companies are German Loesche, Denmark Smith Atox and German Polysius, etc. In China, famous vertical mill companies are BPEG(Beijing Power Equipment Group), Shenyang Heavy Machinery Factory, Hefei Cement Research & Design Institute, Tianjin Cement Industry Design and Research Institute and CITIC Heavy Industries. Since the beginning of the 21st century, domestic vertical mill production equipment technology has become more and more mature, and a large amount of application is put in use.

The functions of various vertical mills in different manufacturing techniques are also different. For cement production enterprises, the solving of the abrasion problem of raw material in vertical grinding system can be the liberator of the whole industry. Wear resistant ceramic metal lining is required for the following components: vertical grinding roller shaft protector(or the guard board), wear resistant ceramic air guide ring( the upper hand ring) scale board, vertical mill cylinder, the inverted inner cone of the separator, bracing piece, separator shell, the fixing guiding vane of separators, feed chute(internal and external wear resistant treatment), tubing protection sleeve, vertical mill-to-the cyclone bobbin duct, cyclone, vertical grinding roll sealing ring and other components.

Over the past 30 years, with high-quality wear resistant products as the leading role, assisted by the research and development of cutting-edge wear resistant products, KINGCERA has made every effort to provide a complete set of equipment wear resistant solutions for industrial and mining enterprises, and has won the recognition and praise of thousands of customers around the world. As a professional wear resistant ceramics manufacturer, KINGCERA is willing to be by your side, as a reliable wear protection expert.