In the

cement raw mill production process, the upper air ring liners of the raw vertical roller mill are subjected to long-term, severe erosion by high-temperature, high-speed dust-laden airflows, making them susceptible to wear-through and necessitating frequent downtime for maintenance; consequently, the wear resistance of the upper air ring is directly correlated with the equipment's continuous operational efficiency and maintenance costs. A cement plant in Nigeria had long been plagued by this issue, where the traditional “8+6 overlay weld composite liners” previously used in their vertical mill upper air ring had an average service life of only 2 months; the frequent downtime for replacement not only affected production continuity but also incurred continuous labor and material costs.

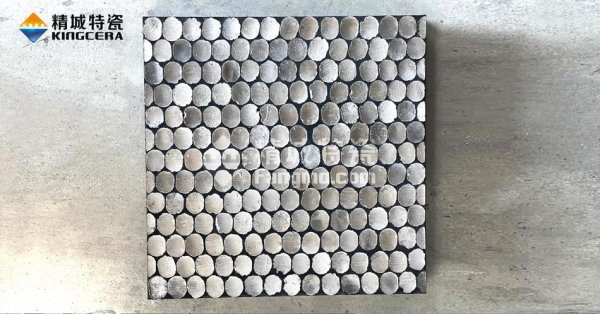

Targeting these operating conditions, Kingcera provided its independently developed

Zirconia Toughened Alumina (ZTA) ceramic liners as a solution. This material combines the high hardness of alumina with the high toughness of zirconia, possessing excellent impact resistance and wear resistance, making it particularly suitable for the vertical mill air ring area characterized by high temperatures, high erosion, and severe abrasion.

On August 27, 2024, the cement plant conducted its first trial of Kingcera’s Zirconia-Alumina Composite ZTA

ceramic liners. As of the time of this publication, the liners have been operating normally for over 14 months and remain in service. Compared to the original material, the service life has been significantly extended from 2 months to over 14 months—an increase in wear resistance of more than 7 times—leaving the customer extremely satisfied and praising “Made in China.”

![[Case Study] Service Life Increased by 7 Times! Kingcera Ceramic Liners Facilitate the Optimization and Upgrade of Vertical Roller Mill Upper Air Ring Liners at a Nigerian Cement Plant [Case Study] Service Life Increased by 7 Times! Kingcera Ceramic Liners Facilitate the Optimization and Upgrade of Vertical Roller Mill Upper Air Ring Liners at a Nigerian Cement Plant](http://www.kingcera.com/zstatic/uploadimg/260210/1442316049-0.jpg)

During the initial installation period (September 19, 2024), the customer reported minor chipping and edge spalling on the ceramic edges. Following technical communication between both parties, it was confirmed that this was a normal microscopic adjustment phase for ceramic materials under high-intensity impact and did not affect the overall structural integrity or protective function. Since then, the ceramic liners have performed stably with excellent anti-wear effects, fully meeting on-site operational requirements.

Based on the validation of 14 months of actual operation, these Kingcera brand Zirconia-Alumina composite ceramic liners have not only drastically reduced the frequency of downtime for replacements but also significantly saved on comprehensive maintenance costs. The customer is highly satisfied with the usage results and has transitioned from initial trial to full confidence—currently placing additional orders for a complete set of vertical mill air ring liners and expanding the application of Kingcera solutions to other equipment.

After 32 years of operation by Hunan Kingcera, the “Kingcera” brand has gained recognition from an increasing number of customers; particularly in international markets, customers are moving away from seeking merely “cheap and good” products to choosing brands with better cost-performance ratios and products with longer lifespans and superior wear resistance, thereby highlighting Kingcera's unique brand appeal and earning global recognition. By providing customized solutions and full-lifecycle services, the company builds an integrated competitive model of “Product + Technology + Service,” allowing customers to genuinely perceive the product value and brand warmth.

Samuel Wu / Translated

![[Case Study] Service Life Increased by 7 Times! Kingcera Ceramic Liners Facilitate the Optimization and Upgrade of Vertical Roller Mill Upper Air Ring Liners at a Nigerian Cement Plant [Case Study] Service Life Increased by 7 Times! Kingcera Ceramic Liners Facilitate the Optimization and Upgrade of Vertical Roller Mill Upper Air Ring Liners at a Nigerian Cement Plant](http://www.kingcera.com/zstatic/uploadimg/260210/1442316049-0.jpg)