The iron and steel industry is an industrial sector mainly engaged in industrial production activities such as ferrous metal mineral extraction and ferrous metal smelting and processing, and is the vane of the country's economic development. In the sintering process of the iron and steel industry, conveying, generally using a thick phase conveying system, the use of airflow, in a closed pipe conveying granular materials, conveying large quantities, long conveying distance, high conveying speed, but there is also heavy wear and tear of the pipeline, frequent replacement, pollution of the environment, affecting the production efficiency, the production line of the iron and steel industry personnel are deeply disturbed by it.

According to the response of the production staff of a steel plant in Shandong, the dust removal fittings in sintering can only be used for about three months in the early stage, and the process of centrifugal pouring material + cement backpack is used. After technical communication with the plant, our company adopted the ZTA ceramic staggered paste process, the feedback from the site has been used for 1 year and 3 months, all the operation is normal, by the customer unanimously praised.

Compared to traditional steel pipes, Kingcera's wear-resistant ceramic pipes have the following characteristics:

Wear and tear resistant: 10-20 times more wear-resistant than ordinary pipes under the same conditions;

Corrosion resistant: Ceramic lining and inorganic binder is excellent for resistance to acid and alkali corrosion;

High temperature resistant: Suitable to work at 150°C for long periods of time in most operating environments;

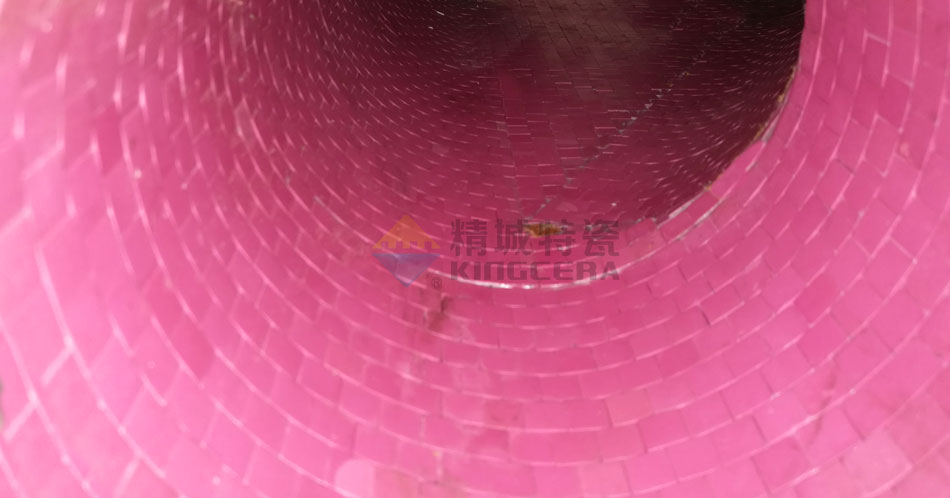

Misplaced pasting: Straight pipes and elbows are lined with ceramic pieces that are all staggered and pasted together, while elbows are staggered and pasted together along 120° of the inner wall of the elbow to prevent the airflow from washing the ceramic along the wind direction; smooth inner and outer walls for smooth airflow: the smooth surface allows the material to pass freely without hanging or blocking the material;

Easy to install: 1/3 lighter than ordinary pipes, our pipes not only are easy to carry, but also saves labour, being easier and faster to install, operators can erect pipes higher easily;

Less maintenance: Superb abrasion resistance allows for much less frequent maintenance, which saves costs and labour.

Hunan Kingcera Engineering Co., Ltd was established in 1993.We have been focusing on the field of wear-resistant ceramics for 27 years, as the national standard GB/T 27979-2011 Alumina Wear-resistant Ceramics National Standard drafting unit. Our general manager Mr. Yang Zheng is the wear-resistant ceramic materials technology research industry leader, but also the inventor of ZTA and ARZ new materials. Choose Kingcera products, to ensure you worry-free.