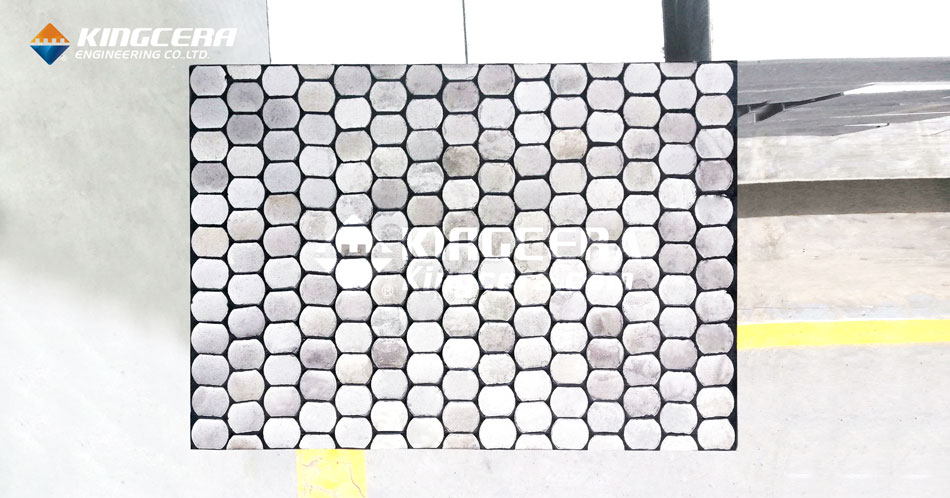

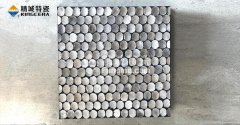

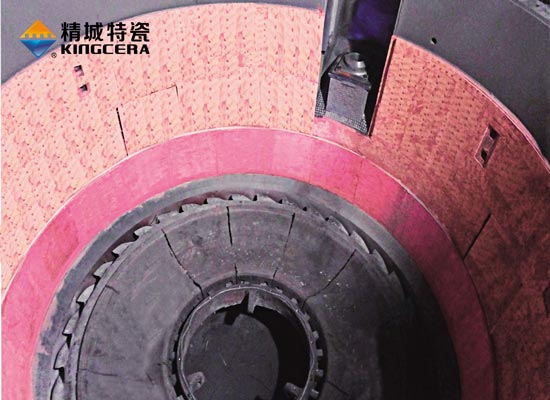

Tic wear liners comprise of Tic insert, moulded in a high tensile strength natural rubber matrix, and mounted on steel backing plates.

All rubber ceramic liners are hot vulcanized together using specialized equipment which provides a bond strength that exceeds the tensile strength of the natural rubber matrix. As a result the Tic insert will remain in the rubber matrix, offering consistent wear and impact protection across the entire life of the liner.

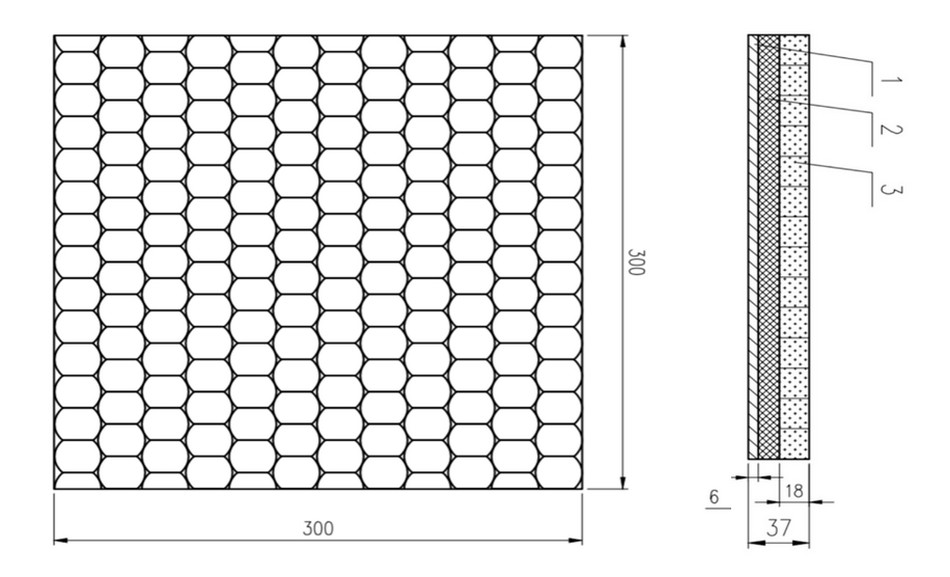

Easy adaptation into existing installations is achieved with the modular liner layout comprising of standard sizes and studs welded to a 6mm steel backing plate, or to other thickness plates as requested. This steel backing plate provides rigidity for easy replacement and standard sized liners are produced for convenience.

Tic wear liners are designed for maximum resistance to impact and abrasion for use in many bulk materials handing applications. With specific focus on maximum abrasive resistance for Iron Ore and other hard rock applications.

Tic Technical Specifications

|

Item |

K-TiC |

|

Component |

Titanium Carbide 48%, high manganese steel and others 52% |

|

Density |

6.10 g/cm³ |

|

Porosity |

A02B00C00 |

|

Hardness HRC |

60-62 |

|

Impact (J/mm2) |

≥ 6.0 |

|

Bending Strength |

≥ 1800 Mpa |

Rubber Technical Specifications

|

Component |

Natural rubber |

|

Tensile Strength (TSB) |

≥ 15 Mpa |

|

Hardness |

60 +/- 5 Shore A |

|

Elongation |

450% |

|

Resilience |

65% |

Application:

---Deflectors/Impact plates

---Chutes

---Bins/Hoppers

---Skirt liners

---Stackers & Reclaimers

Clear advantages:

--- Noise reduction

--- Enhanced wear characteristics

--- Improved flow efficiency

--- Increased productivity