Background

In the new dry process production line, the conveying of powder is mainly powered by the fan. The relative movement of dust-containing particle and the fan caused by high-speed rotation leads to serious wear in impeller.

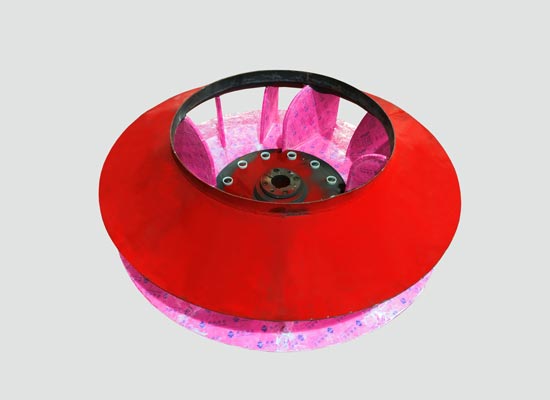

In the market, generally use traditional anti-wear methods such as wear-resistant hard facing welding and thermal spraying, the effect is not always ideal. Hunan Kingcera uses tailored ceramics tile & unique bonding way to make a wear-resistant lining on the impeller. This solution could make sure no fall off during high-speed operation, meanwhile no effect on equipment starting and running.

The wear-resistant ceramic fan impeller produced by Hunan Kingcera is equipped with wear-resistant ceramic linings on the quick-wear parts, providing a series of anti-wear solutions with f dynamic and static balance.

There is a close combination of ceramic and impeller, and the wear-resistant ceramic tile with low density, the total weight is much lower than the commonly used steel wear-resistant liner. The service life of ceramic lined impeller can generally extend more than 10 times, the frequency of impeller replacement be reduced.

Ceramic lined fan impeller advantages

-

Increase life by more than 10 times.

-

Unique process ensures that ceramics do not fall off.

-

No change in impeller process parameters.

-

Total weight increase not more than 10 %, does not affect the fan starting.

Ceramic lined fan impeller application scope:

The application is mainly determined according to the working temperature of the fan. It is mainly used in thermal power plant, powder exhauster, thermal plant, coking plant, cement plant, steel plant blast furnace fan, sintering fan, circulating fan and other conditions of conveying hard particles and corrosive medium.

According to the different working temperature, could divided into three areas:

-

Working range at room temperature: temperature below 120 ℃, using conventional binder;

-

Medium temperature range: 120 ~ 180 °C, using high temperature resistant binder and cold welding technology

-

High temperature range: 180 ~ 380 °C, using ceramic-metal welding + high temperature resistant binder.

Product Exhibition