Product Introduction

The damper is mainly composed of cylinder, blade, main shaft, bearing (or sleeve), shaft seal, and actuator. Under the erosion of hard particles, the main shaft and cylinder base are very prone to wear and failure, which will affect the safe operation and production of the power plant in severe cases.

There are two main reasons in the wear failure of the circular damper:

1. When the air door is open, there is a gap between the blade sleeve and the cylinder. Due to the small space, coal and dust accelerate here, and the high-speed airflow is washed for a long time, causing serious wear of the main shaft, inflexible rotation of the blade, and abnormalities such as jamming. In severe cases, it may cause the spindle to break.

2. When the air door is in the open or half-open and half-closed state, the blades change the forward direction of the air powder, making it directly flush against the cylinder wall or the powder conveying pipe, causing wear failure.

Hunan Kingcra thoroughly solves the problem of wear and failure of the circular air door through the following measures:

1. The shaft neck adopts the structure of inner seal and outer support. Wear-resistant ceramic rings are sleeved on the wear parts of the main shaft, and ceramic cylinders are also installed on the frame support sleeve to form a relative moving. This design protects the main shaft from erosion and abrasion, completely solves the problem of shaft jamming, fracture, etc., ensuring that the circular air door has low running resistance, no jams, and flexible rotation;

2. Install wear-resistant ceramic liner on the air door cylinder and blades to solve the abrasion problems caused by feeding material erosion;

3. Properly extend the length of the air door cylinder, and install wear-resistant ceramic tile inside, so that the wind direction of the air powder mixture is converted from the angle to the level, so then the powder conveying tube connected to it is no longer worn.

The service life of ceramic lined damper is at least 5 times longer, it can obtain considerable economic benefits at a lower cost.

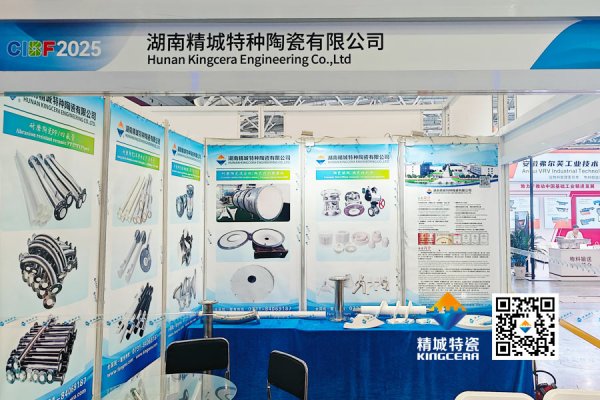

Product Display