Related background:

The cyclone has the advantages of small equipment size, small footprint, low power consumption throughout the year, high classification efficiency, large production capacity, no moving parts, and small maintenance workload. The heavy-medium cyclone can sort any optional coal. It is widely used for classification operations in the grinding process of non-ferrous and ferrous metal mines. It can also be used for operations such as gold separation, concentration, tailings damping, kaolin separation, coal separation, and pulp slag removal.

The cyclone separates solid and liquid by the centrifugal force that generated by the incoming slurry flow. The particles with large mass move towards the wall of the cyclone and accelerate downward in a spiral shape, then discharged from grit chamber. The particles with small mass move to the center of the cyclone under the action of the axial velocity field force, then discharged through the overflow pipe.

There is no doubt that the heavy-medium cyclone is severely worn, including the nozzles, cones, connecting pipes, pipes, pumps and valves of the cyclone, which need to be adjusted or replaced frequently. These will affect the quality and efficiency of coal preparation.

Product Characters

Hunan Kingcera developed various cyclone linings by taking high quality corundum ceramics or high wear-resistant composite ceramic materials. The excellent wear resistance can ensure the cyclone under continuous and stable working conditions, the service life is 4-6 times that of ordinary polyurethane materials, and the cost performance is very high.

1. Tailored ceramic liner design according to the shape of cyclone cylinder, cone tube, outlet tube and other parts, keeping ceramic lining structure reasonable and no gap;

2. 20-25mm thickness ceramic liner under 100 tons dry pressing with high density and excellent wear resistance;

3. adopting high-strength binder and staggered ceramic liner layout, keeping no fall off. Very suitable for harsh working conditions such as high temperature, high impact or dynamic operation;

4. Inside ceramic lined cyclone, inner wall and the material could keep smooth flow, which can maintain the maximum tangential velocity of the slurry in the cyclone, reduce energy loss, and obtain a very good classification and concentration effect.

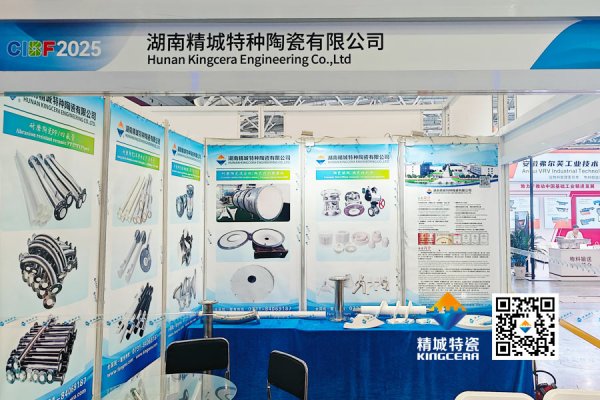

Product Exhibition