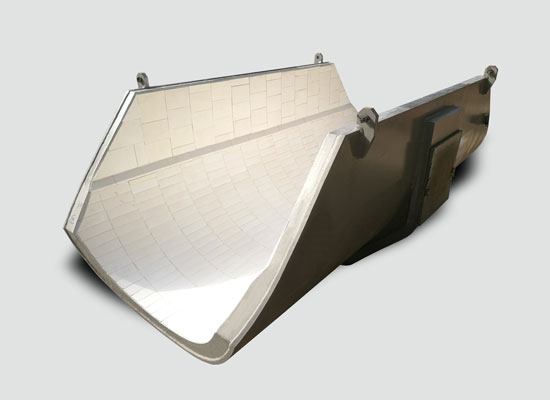

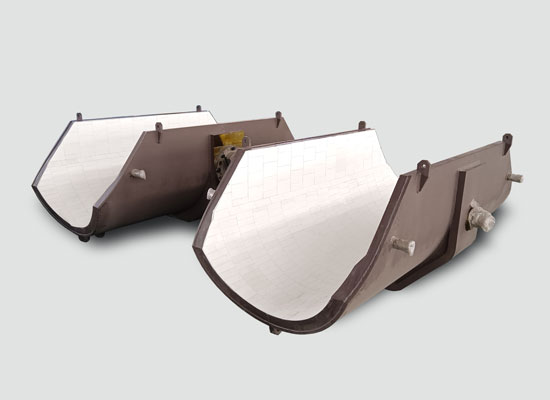

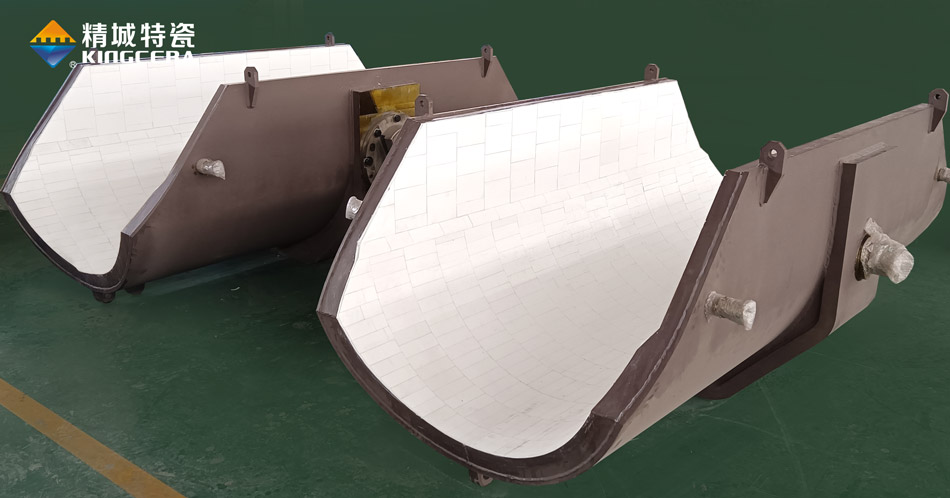

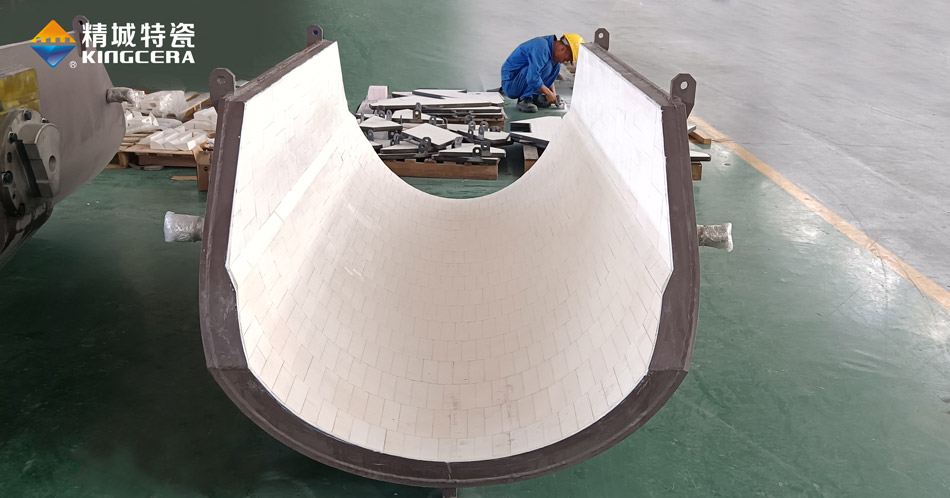

Summary: Ceramic lined swing feeding chute in steel making plant, the bottom and inner wall of which be installed wear-resistant ceramic liner, could extend the service life of the chute, reduce maintenance times and replacement cost.

Application Background: The top equipment of blast furnace in steel making plant includes chute, hopper, fabricator and others device, a raw material mixing & distribution system. This system mix the raw materials and fuels in a certain proportion, usually the top equipment of blast furnace should meet the following conditions: 1. evenly distribution, flexible transfer; 2. good sealing, withstand high furnace pressure; 3. easy maintenance; 4. steady running , safe and reliable operation; 5. wear-resistant, impact-resistant, long service life. Swinging chute is an important component of furnace top equipment, its service life, the number of overhaul will directly affect the efficiency of the blast furnace.

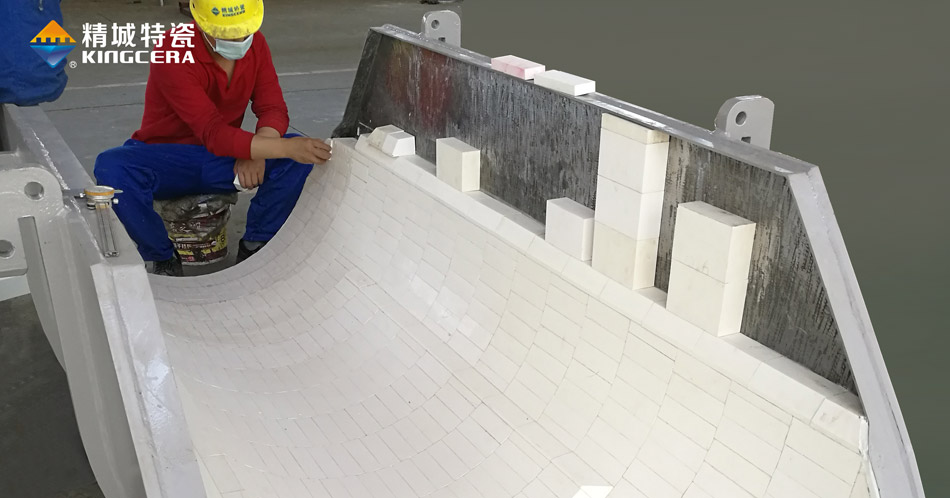

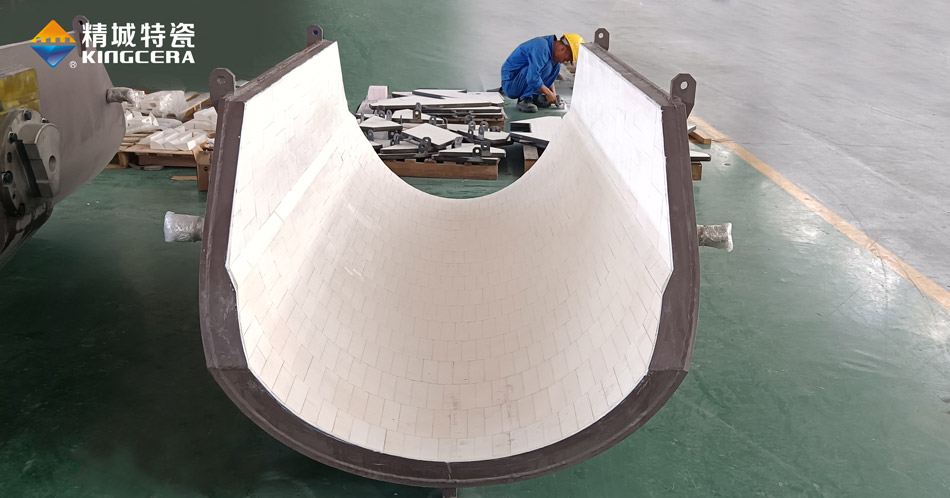

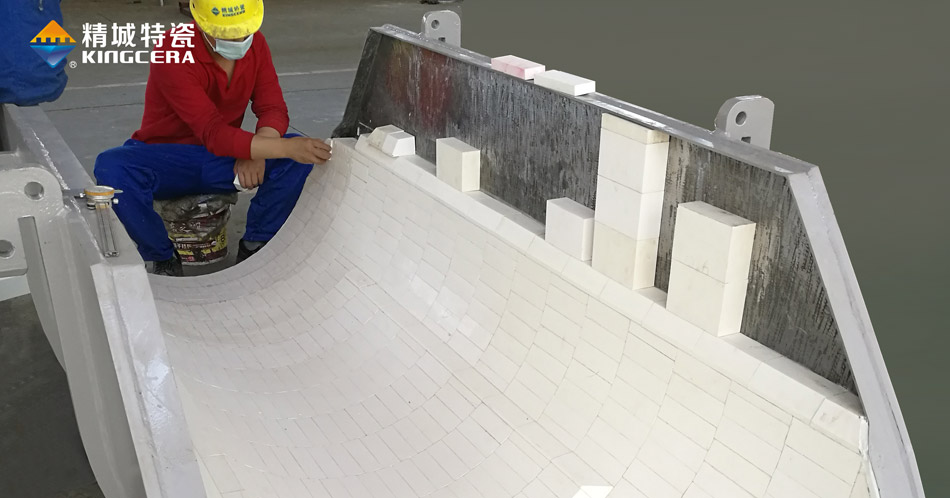

Swinging chute’s working characteristic is large material flow, strong impact, meanwhile ore, pellets and other materials from the height in continuous fall, will cause serious wear and impact, the bottom of the chute is particularly serious. Installation of wear-resistant ceramic liner at the bottom and inner wall of the swing chute can effectively improve the working condition.

Swing chute ceramic liner selection: 95% or 99% high-purity alumina ceramics, high impact area consider ZTA ceramic liner. The size and shape of the ceramics can be designed according to customer needs and equipment shapes. However, it should be noted that the bottom of the swing chute in the iron and steel plant will bear large impact, so the thickness of the ceramic is at least 70mm thickness.

Application: Ceramic lined swing chutes can be used in many fields such as steel plants, cement plants, thermal power plants, mines, etc. However, the wear-resistant ceramics used will vary according to different working conditions. In addition,Hunan Kingcera provide anti-wear design and installation services for other heavy wear areas of furnace top equipment.

Products:

ceramic lined swing chute

ceramic lined swing chute in steel making plant

ceramic lined chute

ceramic liner installation

(Original link:

https://www.fangmo.com/taocishebei/baidongliucao.html; Rachel / Translated)