Kingcera team offer optimized ceramic wear solution for Cement Plant in Sichuan.

CASE

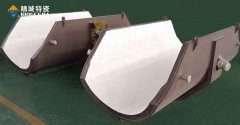

Transfer Station Insert Chute

Material Handled: Limestone

Tonnage: 2,400-3000 tonnes per hour

Particle size: 30-50mm

Drop height: 8-10m

The image as below show the state of the liners were holed after only 28 weeks after installation. The wear of some liners is so severe that the steel backing plate had worn through and into the parent metal of the equipment. This means the material has direct contact with the chute and therefore has the possibility to directly generate a stoppage to repair the equipment.

The cost of replacing worn down consumables makes up a substantial proportion of the total maintenance expenses, so anything that can be done to reduce wear and increase equipment lifetime will have a significant impact on operating cost. The

ceramic wear liners can contribute significantly to reducing maintenance costs and equipment downtime.

Solution:

In close consultation with the client, Kingcera designed and manufactured custom ceramic wear liners to exceed the requirement of the customer, 50mm thick ceramic tiles installed as 63mm thick composite ceramic wear plates.

The client highly appreciate our professional and promise we can work together for more project as long as this case is successful, such as ceramic lining pipe spools etc.