Product Introduction

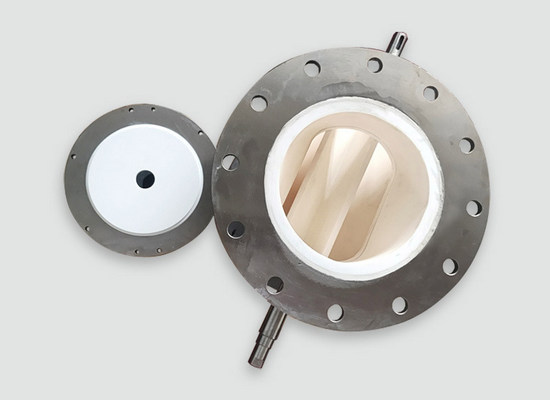

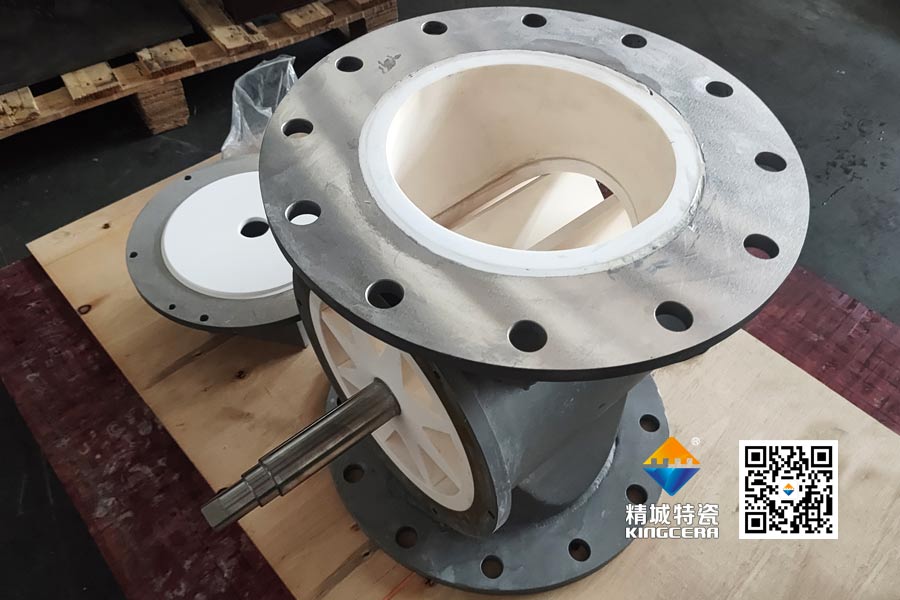

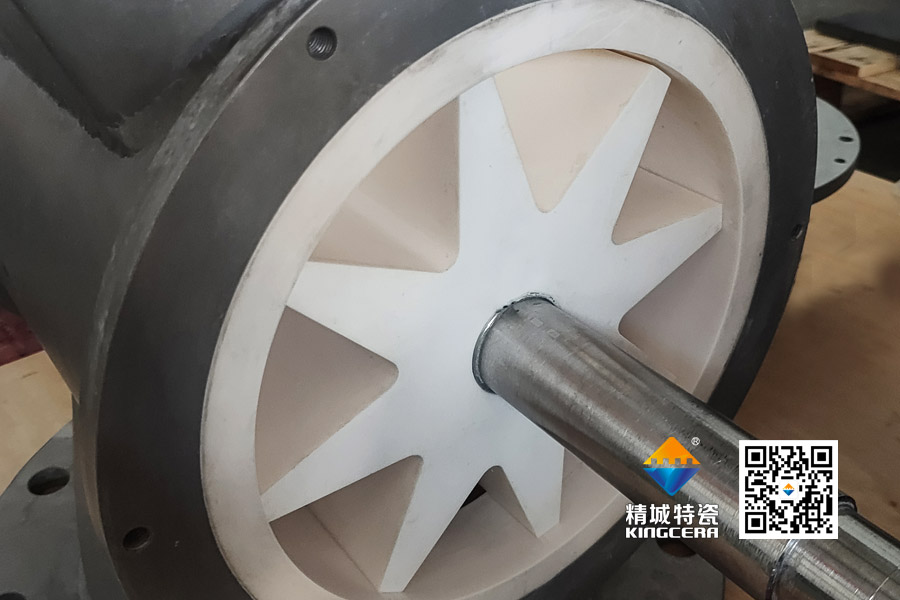

The ceramic rotary valve is a precision feeding device designed specifically for high-abrasion and highly corrosive working conditions, manufactured with an integral ceramic structure; available materials include K95, K99 Alumina Ceramic, ZTA Ceramic, and ARZ Ceramic, featuring ultra-wear resistance, corrosion resistance, and high precision. The clearance between the alumina or zirconia ceramic rotor and the cavity can be controlled to within 0.1 mm, ensuring excellent sealing performance and metering accuracy, making it suitable for the conveyance and metering of powders, granules, and slurries under severe operating conditions.

Ceramic Rotary Valve | Star-Type Unloader Ash Discharge Valve

Working Principle of the Rotary Valve

The rotary valve operates via a motor that drives the rotor (impeller) to rotate; material enters the valve cavity through the inlet and is carried by the impeller blades to the outlet for discharge. Its precision structure ensures continuous, stable, and controllable material conveyance while maintaining system airtightness (applicable to both positive and negative pressure systems).

Operating Condition Analysis and Major Challenges Faced by Standard Rotary Valves

Wear Issues: When metal valves convey hard materials such as cement and mineral powder, the blades and casing are prone to abrasion, leading to increased clearance and material leakage.

Corrosion Issues: Acid, alkali, and salt media in the chemical and metallurgical industries can corrode metal valve bodies, thereby shortening their service life.

Adhesion Issues: Materials tend to adhere to metal surfaces, affecting metering accuracy and potentially causing blockages.

Metal Contamination: The pharmaceutical and lithium battery industries require absolute freedom from metal contamination, yet ordinary stainless steel valves may still generate trace metal particles.

Addressing these issues, Kingcera has researched and produced ceramic rotary valves, which have been introduced to the market and have received positive feedback.

Features and Advantages of Ceramic Rotary Valves

Wear Resistance: Ceramic hardness (HRA ≥ 88) far exceeds that of metal (Stainless Steel HRA ≈ 60), making it particularly suitable for high-wear materials such as cement, mineral powder, and fly ash. The wear resistance of K95 ceramic is more than 10 times that of high-chromium alloys, capable of extending service life by more than 3 times.

Corrosion Resistance: Ceramics possess stable chemical properties, resisting acids, alkalis, and salt spray, making them suitable for corrosive environments such as chemical engineering and hydrometallurgy. It also eliminates the electrochemical corrosion issues associated with metal valves.

High Precision and Sealing: The clearance between the ceramic rotor and the cavity is ≤ 0.1 mm, which is far superior to metal valves, reducing material leakage and improving metering accuracy. Kingcera also possesses complete post-processing equipment, allowing for precision polishing of the ceramic surface according to customer requirements to reduce material adhesion, suitable for sticky powders (such as titanium dioxide and starch).

Contamination-Free: The 100% ceramic structure ensures no metal ion precipitation, meeting the cleanliness requirements of the food, pharmaceutical, and lithium battery industries.

Low Maintenance Cost: Long service life reduces the frequency of downtime for replacements, resulting in a lower comprehensive cost compared to metal valves.

Scope of Application

Chemical Industry: Conveyance of corrosive powders such as titanium dioxide, fertilizers, dyes, and pesticides.

Power/Environmental Protection: Fly ash, desulfurization gypsum, and precipitator ash discharge.

Mining/Metallurgy: Iron ore powder, bauxite, metal powders, and smelting slag.

New Energy: Lithium battery positive/negative electrode materials and photovoltaic silicon powder.

Building Materials Industry: Cement, ceramic powder, and quartz sand.