1、Directly adhesive type

Process characteristics: simple installation, low cost, and firmly bonding, very suitable for large-scale construction on site.

Process introduction: construction process and the glue are the critical items. Ordinary epoxy glue in the market used in wear-resistant ceramic tile lining is mainly organic and has disadvantages that are not resistant to high temperatures (max 150 ℃), and it is easy to be invalid. It can not meet the requirements of long time running. Especially in the case of sudden cooling and sudden heat, the thermal expansion parameters of the ceramic tile and the steel-based material are different, and the organic glue is more brittle, the whole ceramic lining is very easy to peel off.

The GWJ series of high temperature resistant inorganic adhesives we used, jointly developed by Hunan Kingcera. and Tsinghua University. The adhesive is used for bonding steel and ceramic tile, high strength, good toughness, can be cured at room temperature, and excellent heat resistance. Basing on our years record and feedback from customers, our patented glue technology is mature and reliable.

Application scope: dust collecting pipeline, coarse and fine powder separator, coal mill outlet pipe, branch pipe and air pipe, cyclone, powder exhauster, powder separator, magnetic separator, V separator, fan volute, etc.

2、Welding type

Process characteristics: double fixation, good reliability, high temperature resistance up to 750℃

Process introduction: In addition to directly adhesive glue between steel base material and ceramic tile, pre-design the ceramic tile shape, leave a center cold welding hole. When both be finished, could achieve the effect of double insurance. The cold welding type is suitable for high temperature pipes (up to 750°C) or slight impact, such as the inlet and outlet pipes of the humidification tower, the dust collecting pipes at the kiln tail, etc.

Application scope: hot air duct, secondary/tertiary duct, flue wall, support rod, air preheater baffle, etc.

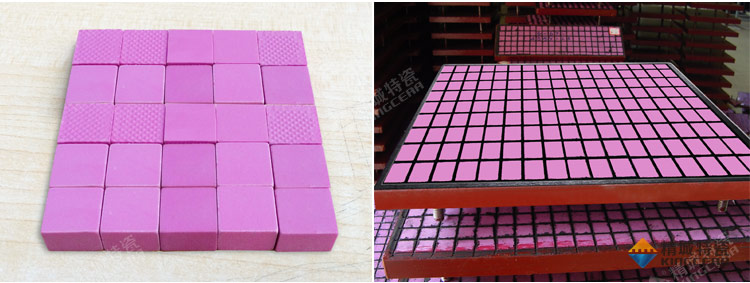

3、Rubber vulcanization

Process characteristics: ceramic tile, rubber, steel plate in 2 in 1 or 3 in 1 ceramic liner by vulcanization process. Strong resistance, easy to replace, suitable for impact and abrasion of bulk materials conveying system and temperature below 120℃

Process introduction: Multiple selection, 2 in 1 ceramic liner:ceramic tile & rubber liner, ceramic tile & steel plate liner; 3 in 1 ceramic liner: ceramic tile, rubber, steel plate liner;

Application scope: chute, hopper, drum, coal drop hopper, coal drop pipe, raw coal bunker, coal mill inlet and outlet pipe, etc.

4、Dovetail tile & steel bar mechanical fixing type

Process characteristics: firm installation, high temperature resistance, suitable for moving parts, but the fixing method is much more complicated

Process introduction: Pre-design the ceramic tile in dovetail shape, combined with steel bar, plus cold welding and mechanical installation. This method is mature and reliable, can withstand high temperatures below 1000 ℃, especially suitable for the wear resistance of moving parts, such as fan impellers.

Application scope: fan impeller, high temperature flue, waste heat power generation pipeline of cement plant, sintering dust removal pipeline, etc.