The scope of application of ceramic pulley lagging

It is used for preventing the pulley from wear, slip and deflection.

Ceramic Pulley Lagging Introduction

The traditional pulley is covered with rubber to prevent the belt from slipping. However, there are also shortcomings in practical applications, especially in the open-air conveying system. The surface texture of the roller will be worn away in a short time under the abrasion of the material and the belt. In rainy days, the belt is easily stained with mud and the belt slips, which seriously affects the conveying efficiency, and even makes the belt line unable to operate normally and has to be shut down for replacement.

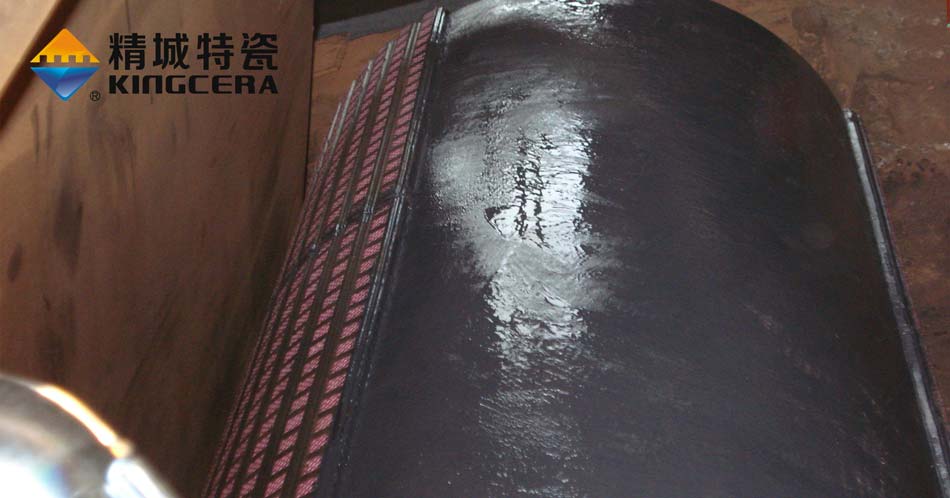

Kingcera's new generation of ceramic pulley lagging (NMC-B) uses a thermal vulcanization process to vulcanize wear-resistant ceramics with bumps on the surface in a special rubber according to a certain layout, and then paste it on the surface of the roller to replace the traditional rubber, to enhance the friction coefficient between the belt and the pulley and increase the service life of the Pulley. At the same time, the groove between each row of ceramics facilitates drainage and mud removal, ensuring normal operation in harsh environments.

Features of the ceramic pulley lagging

■ Long service life: there is almost no wear on the surface ceramics, and the service life can reach 8-10 times that of traditional rubber encapsulation;

■ Thoroughly solve the problem of belt slippage and deviation: Under normal conveying pressure, the ceramic bump design can ensure the positive traction of the belt, prevent the conveyor belt from slipping and deviation, and improve the conveying efficiency;

■ Belt maintenance: The traditional rubber lagging cannot clean the material and muddy water on the belt, and it is easy to damage the belt and drum. The unique convex point design and groove design on the surface of the NMC-B ceramic pulley can play the role of cleaning the material on the surface of the belt and draining mud, so that the ceramic and the belt are tightly engaged without sliding friction between each other, and there are many convex points. Uniform force exerts a good maintenance effect on the belt.

■ The groove between each row of ceramics is convenient for drainage and mud removal.

Product Display