PRODUCT DESCRIPTION

Concrete pump trucks are widely used in modernization construction. During the pumping process, the boom pump pipe wall are suffering severely abrasion problems caused by both high conveying pressure and sliding of gravel and concrete slurries, which finally lead to a higher costs and frequent maintenance, also the pump operators will suffer great loss. Therefore, it is essential for us to find out a more economically and feasible materials which can greatly extend the service life of the pump pipes, which is of significance not only for improving equipment production efficiency, but also minimize production costs and saving resources.

After years of study and full research, KINGCERA developed its own abrasion-resistant ceramic lined boom pump pipe systems, also known as “KCPP pump pipelines” , This pipe were developed on the basis of full research from various brands of boom pump trucks under different operating conditions, with dynamic mechanical pipeline optimization, the pipe was fully lined with high-strength abrasion resistant ceramic linings in order to protect the inner wall and minimize the abrasion problems caused by the flow slurry.

EXISTING PROBLEMS FOR NORMAL BOOM PUMPING PIPES

1. Short service life time, frequent shut down and maintenance, not good for pumping operation

2. High weight of pipe, not good for replacement and repairmen.

MECHANISM OF BOOM PUMP PIPE WEAR LOSS

KINGCERA has conducted many surveys and tracked for the use of pump pipes from various truck pump companies, finally we found that the service life of the pump pipeline is not only related to the material of the pipeline itself, but also directly related to the physical properties of the content of concrete (mainly for sand and gravel hardness, also particle size) and the flow impact angle has the greatest influence.

1. Particle shape and size

Based on our observation, the concrete which contain pebbles had little impact abrasion to the pipelines, while the crushed gravels will shorten the service lifetime of the boom pump pipes.

2. Working pressure and flow rate

For a same truck boom pump, different part of the pipeline will meet with different wear problems according to the working pressure and flow rate. Under normal circumstances, the first elbow and the last elbow of the pipeline will suffer from greatest wear and abrasion problems.

3. Flow impact angle

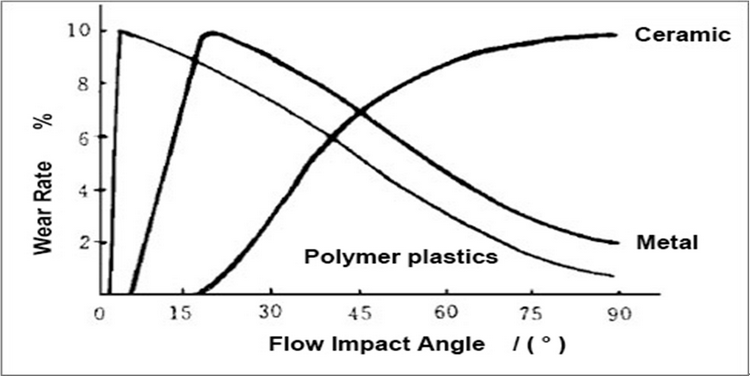

The result showed that the abrasive wear is the main cause when the flow impact angle is 0 degrees. As the angle increases, the abrasive wear decreases and the proportion of surface fatigue wear increases accordingly. When the angle is 90 degree, the surface fatigue wear becomes domination cause, the material with good toughness will of low wear rate. For example, rubber is the best anti-wear material for a flow impact angle of 90 degrees but the worst material when the angle becomes 0 degrees.

The relationship between material and flow impact angle

It can be seen from the above picture that the wear loss of ceramic material is the smallest when they are working under a small flow impact angle. The worn-out of the boom pump pipe is the result of the combination of abrasive wear and surface fatigue wear. Whether it is a straight pipe or an elbow, abrasive wear occupies for the dominant factor, so it is not appropriate to use mild steel witch of lower hardness. In order to improve the service life of the pipeline system, it is necessary for us to find a material with higher hardness and toughness that can take the place of traditional mild steel pipeline. Abrasion resistant ceramic tile linings have extremely high hardness and high toughness, which are ideal materials for solving the wear problems for boom pump pipelines and they are widely used home and abroad.

Advantages of KCPP boom pump pipeline

1. Super abrasion resistance and 10 times longer service lifetime than ordinary pipelines.

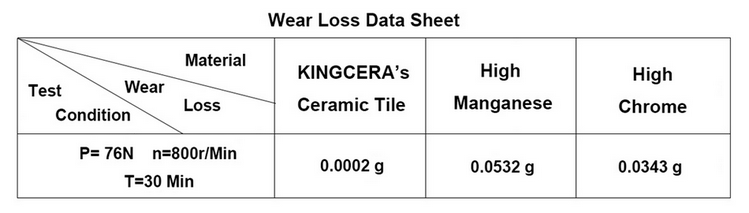

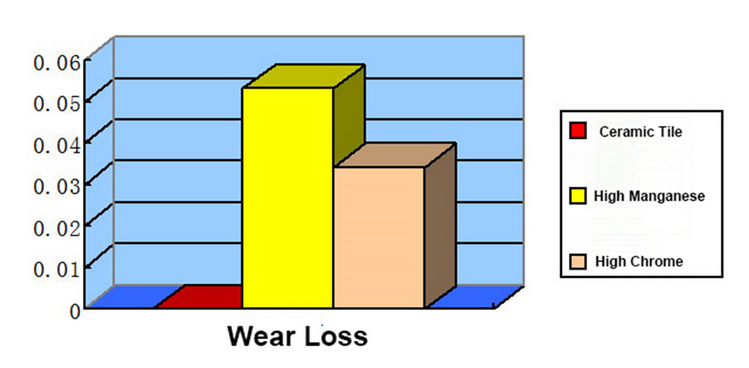

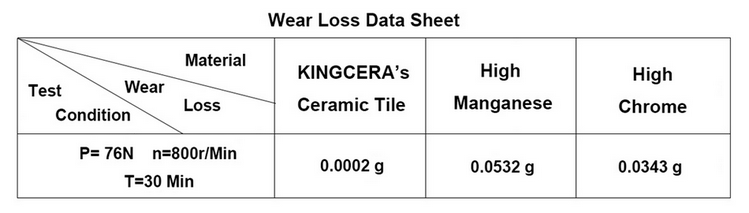

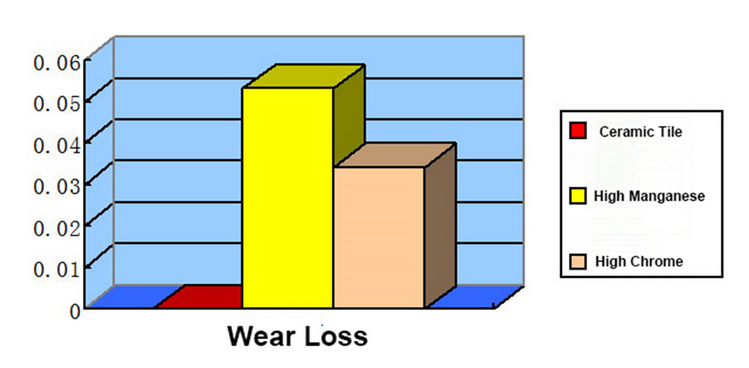

The worn-out of the boom pump pipe is the result of the combination of abrasive wear and surface fatigue wear. It is not wise to increase the hardness of the material or improve the toughness of the material itself. We should better make some combinations of the materials we choose and obtain the best hardness and toughness. In order to achieve this goal, we have cooperated with Tsinghua University to develop high-strength wear-resistant ceramic linings which will be suitable for concrete conveying through continuous experiments and improvements. KINGCERA uses the alumina as the main raw material and adding a variety of rare elements and sintering it through well-controlled procedures. Finally we get the excellent abrasion-resistant ceramic tile linings with hardness more than 90HRA, which is next to diamond. A report provided by the Institute of Powder Metallurgy of Central South University have indicated that he wear-resistance performance of ceramic linings is about 266 times that of manganese steel and 171.5 times than high-chromium cast iron.

Above experimental data is measured by MC-730 friction testing machine under the conditions of pressure P=76N, mechanical speed n=800 rpm, and test time of 30 minutes. According to the calculation of the wear loss, the wear-resistance of KINGCERA’s ceramic tiles is equivalent to 266 times of manganese steel and 171.5 times that of high-chromium cast iron.

2. Super impact resistance

KINGCERA’s unique formula helps to form a strong crystal bonding and structural, which greatly enhances the impact resistance of KINGCERA’s abrasion ceramic tiles. The fracture toughness of the ceramics can reach 7Mpa•m1/2, which is 1.5 times than ordinary ceramic linings. So they could be applied under very harsh conditions with excellent performance.

3. Light weight, quick and easy installation

The density of ceramic is 3.8g/m3, which is only weight half than normal steel. For a same size boom pump pipe, KINGCERA’s KCPP pump pipe is about 20% lighter than ordinary cast steel pipelines. For example, “KCPP 125A90DR275” elbow is only 13.7kg, which is 28% lighter than a cast steel elbow. The lighter weight makes it easier for replacement and greatly reduces down the whole truck loading.

4. Reduce the frequency of maintenance and replacement

Greatly extend the service life, reduce down the frequency of maintenance, replacement, and the operating cost of the pump truck.

5. Good compression resistance, safe and reliable

The KCPP pipeline is made of 20# seamless steel pipe, with good sealing performance and good compressive strength of ceramic linings as 1300MPa, which can fully meet the pressure requirements of various types of boom pump truck pipelines.

6. Smooth inner wall ensures a better flow pump capacity

The KCPP concrete pump pipe contains unique self-lubricating ceramic tiles, which could reduce down the coefficient of friction and blockage. The installation process of ceramic linings are carried out strictly in accordance with Q/OKVL001-2003, to ensure a smooth transition surface of the tiles, the maximum height difference should not exceed to 1mm.

7. Superior cost-effective performance

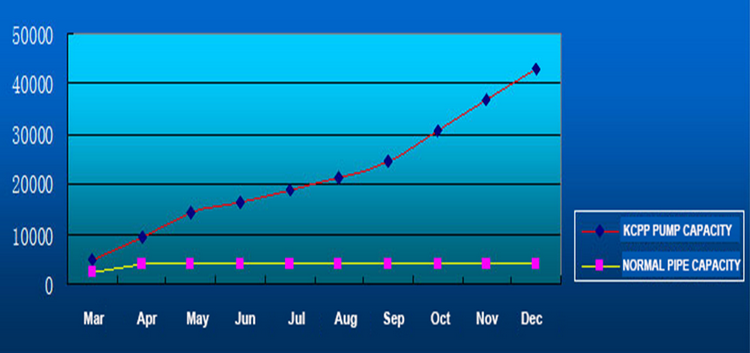

KINGCERA provided a set of KCPP concrete boom pump pipelines to JINAN JINSHENG CONCRETE CO., LTD in March 2008 as a trial use. At the same time, there was another set of ordinary pump truck pipelines. The two sets of pump truck pipelines were installed on 48-Meter pump. With the same experimental test condition, the ordinary elbow pipe was worn-out after 4000m3 pumping job, and the KCPP pump elbow were continuously working through 10 months with a total pumping capacity of 43026.5m3.

Application of KINGCERA’s KCPP pump truck pipeline

BRAND: ZOOMLION/ SANY/ PUTZMEISTER/ XCMG/ CIFA/ HAINUO/ ISUZU/ SHANTUI/ KYOKUTO/ IHI/ SCHWING/ JARLWAY/ HOLD ETC.

PIPE TYPE: HBT30, 40, 50, 60, 70, 80 concrete pump pipelines.

HBT30、40、50、60、70、80