Features of the ceramic pulley lagging

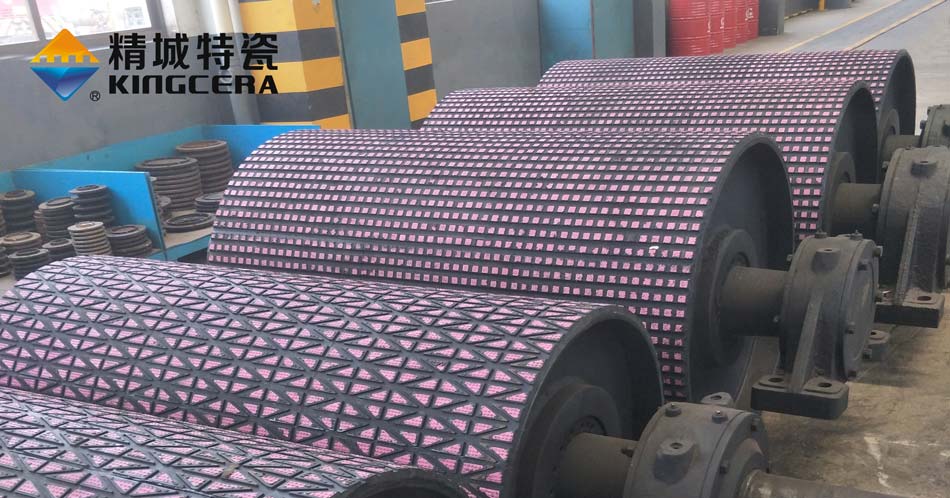

The surface of the wear-resistant ceramic Pulley of Kingcera belt conveyor and the ceramic roller of the conveyor belt is made of convex corundum ceramic anti-wear layer to increase the surface friction, and then bonded with the pulley with a high-strength ceramic metal adhesive. The lifetime of the ceramic pulley lagging is more than 10 time than the rubber lagging.

Features of the ceramic pulley lagging

Compare to the traditional rubber lagging, the ceramic pulley lagging has the following advantages.

1. Excellent wear resistance and long service life performances

Measured by the Institute of Powder Metallurgy of Central South University, the wear resistance of special ceramics is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. According to on-site operation experience, the durability of the belt conveyor ceramic roller and the conveyor belt ceramic roller is at least 5 years, which reduces the frequency and cost of maintenance. Practice has proved that the service life of ceramic pulley lagging is more than 10 times that of traditional rubber lagging.

2. High friction resistance, no slipping

After a period of wear of the traditional rubber anti-wear layer, the surface becomes smooth, which can easily cause the belt to slip and deviate. There are bumps on the surface of the ceramic sheet, the roughness is high, and the friction coefficient between the ceramic and the belt is large, so continuous operation is not easy to slip and deviate.

3. Strong ceramic bonding

During the construction process, the liner is glued to the metal cylinder with a high-strength ceramic metal adhesive, and then squeezed tightly so that there is no gap; at the same time, the contact surface of the ceramic and the roller has a unique "dovetail groove" design. The ceramic and the roller Ensure that the thickness of the inter-adhesive is more than 1mm, and the bonding shear strength is more than 12Mpa to ensure that the ceramic sheet does not fall off.

4. Easy to installation

The construction technology is mature, simple and short. After the steel structure is completed, an installation worker can generally complete the installation of a ceramic pulley lagging within one day, which does not delay the production and facilitates the user to put into production in time.

5. The groove between each row of ceramics is convenient for drainage and mud

The ceramic pulley has a unique drainage ditch structure design of our company, which can drain rainwater and scattered powder from the ditch as soon as possible.

Product display: