Product Introduction

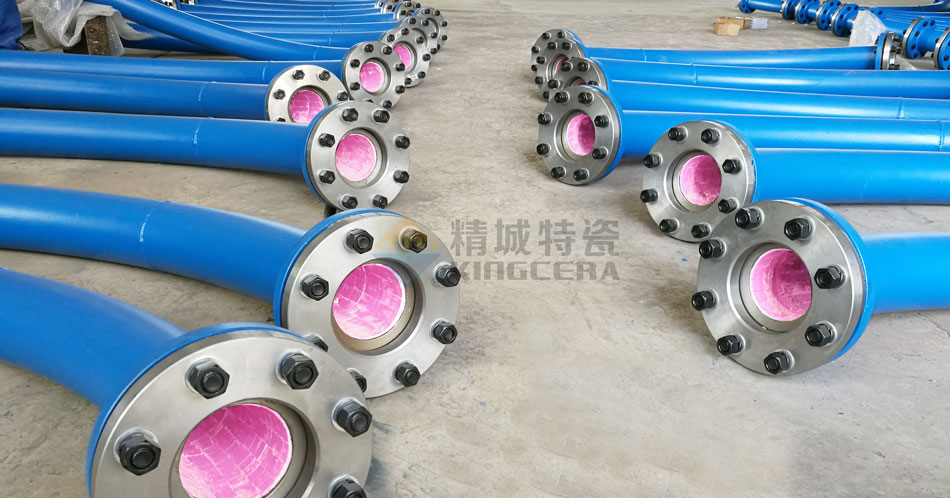

Wear resistant ceramic lined pipe bends are made by installing special ceramics on the inner wall of the pipe with a high-temperature resistant inorganic adhesive, and forming a firm wear protection layer after being heated and solidified. Wear resistant ceramic lined bends have the performances of high wear resistance, long service life time, and easy installation, and significant economic benefits, widely used for the cement plant, melting, coal power plant, mining and so on.

The pulverized coal transportation and dust removal system pipelines are used to transport high-temperature gas mixed with hard particles. Its operating characteristics are high temperature, high flow rate, high particle hardness, and serious equipment wear, especially the elbow part. The life time is general just one year if there is no protective measures are taken. Most of these equipment are on high-altitude supports, which is inconvenient for maintenance. Once worn out, it will seriously affect the safety.

Kingcera Wear-resistant ceramic lined bend adopts a special design, so that after the last piece of a circle is embedded, a 360° mechanical self-locking force is formed between the ceramic tiles to ensure a tight ceramic bonding. The GWJ series adhesive used for pasting ceramics is a proprietary product jointly developed by our company and Tsinghua University. The adhesive has excellent adhesion to steel and ceramics; it has high strength and toughness; Heat resistance and aging resistance. It can be operated at a temperature of -50°C to 350°C for a long time.

Performance comparison

The Wear-resistant ceramic lined bend can be favored by the market and continue to replace some traditional anti-wear materials. The fundamental reason lies in its excellent product quality and its advantages compared with traditional anti-wear materials such as cast Basalt and cast steel.

1、Basalt

In the past, most of the factories use the basalt bends. This material is characterized by fragility, cracks. It usually with 25-35mm thick wear surface backpacks, some are nearly 40 mm. The inner side is ground for a short time. After breaking and cracking, the pulverized coal wears outward along the gap, and its life span will only have one major repair period. Moreover, there are often pores inside, which are easy to leave hidden dangers. Once worn through, the site cannot be repaired.

2、Cast Steel

Cast steel (including alloy steel) is widely used in the field of wear resistance, and its manufacturing process is relatively simple. However, due to the limitations of the performance of the material and the limitation of the process, the surface hardness of cast steel materials (about 60) is much lower than that of ceramics (above 80), and the wear resistance is only equivalent to a few tenths to lower than that of ceramics. (Specific For the data, refer to the wear test report of the Institute of Powder Metallurgy of Central South University and the spray wear test results of the Kyushu Industrial Ceramics Research Institute of Japan). In addition, the cast steel pipeline is thick, very heavy, and has a high carbon content, and the weldability is relatively poor. It requires on-site butt weld heat treatment, which brings considerable difficulties to on-site installation and maintenance.

Product features of wear-resistant ceramic lined Bend

-

Wear resistance: high-quality alumina ceramics with hardness above HRA85, which is more than 10 times of life time than ordinary pipes;

-

High temperature resistance: It can be worked under the 350oC for a long time.

-

Anti-vibration and thermal expansion and contraction: The thermal expansion coefficient of viscose is between steel and ceramics, which can well adjust the extrusion of ceramics due to the inconsistency of thermal expansion between ceramics and steel; at the same time, a variety of flexible fibers are added to viscose, To ensure that the ceramics will not fall off for a long time under the environment of vibration and frequent thermal expansion and contraction;

-

Erosion resistance: it can resist the erosion of larger particles without breaking;

-

The inner and outer walls are smooth, and the air flow is unobstructed: the smooth surface allows materials to pass freely without material hanging and blocking;

-

Easy installation: 1/3 lighter than ordinary pipes, easy to carry, save manpower, easier and faster to install, and can easily erect higher pipes;

-

Low cost: reduce the load of support and hanger equipment and save material costs;

-

Reduce maintenance: The super abrasion resistance greatly reduces the frequency of maintenance and saves costs and labor.

-

Product Display