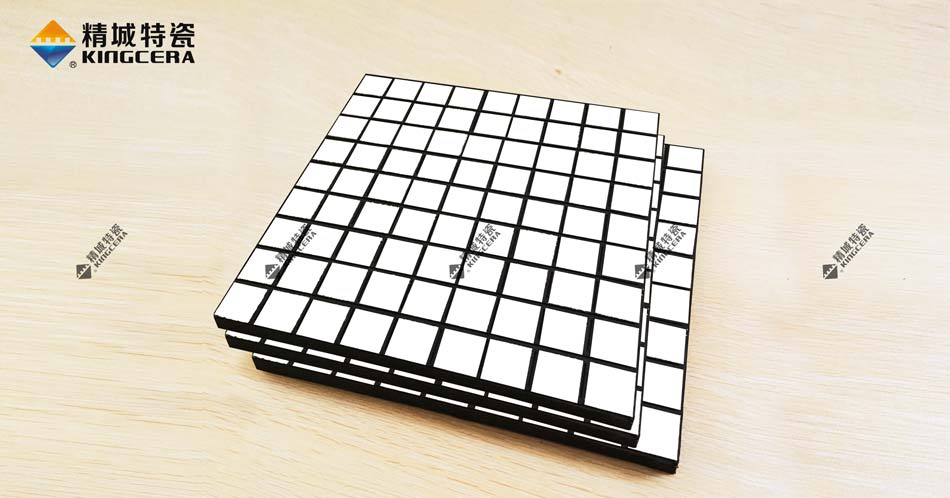

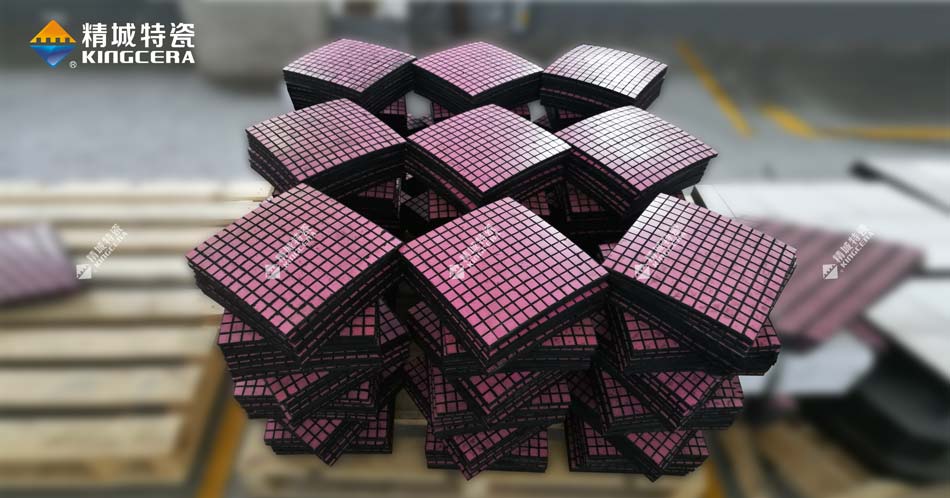

The ceramic rubber liner adopts a hot vulcanization process to vulcanize toughened and wear-resistant ceramic and rubber together to form a ceramic rubber liner. It combines the high hardness of ceramics,the high impact resistance and anti-fatigue pro

Brand:KINGCERA

Origin:Changsha China

Categories:Ceramic wear liners

FEEDBACK| Item code | Sizes(Liner/Ceramic tile) | ||

| NMC-J1 | 250*250*10/17.8*17.8*5 | ||

| NMC-J2 | 250*250*14/17.8*17.8*7 | ||

| NMC-J30 | 17.8*17.8*12 | Rubber thickness=8 | Total thickness=20 |

| NMC-J31 | 17.8*8.9*9(Groove) | Rubber thickness=10 | Total thickness=19 |

| NMC-JZ35 | 17.8*17.8*12(ZTA) | Rubber thickness=7 | Total thickness=19 |

| NMC-J38 | (35+34)/2×20×12 | Rubber thickness=18 | Total thickness=30 |

| NMC-J39 | 17.8*17.8*12 | Rubber thickness=5 | Total thickness=17 |

| NMC-J42 | (29+30)*15*12 | Rubber thickness=12 | Total thickness=24 |

| NMC-JL3 | 250*250*14 | 10.7(Side length)*7(Hex) | |

| NMC-JL4 | 250*250*20 | 10.7(Side length)*10(hex) | |

KINGCERA Achieves New Milestone in Overseas Project:Ultra-Wear-Resistant Ceramic Technology Boosts Efficiency for Coal Washing Plant

05-24-2025

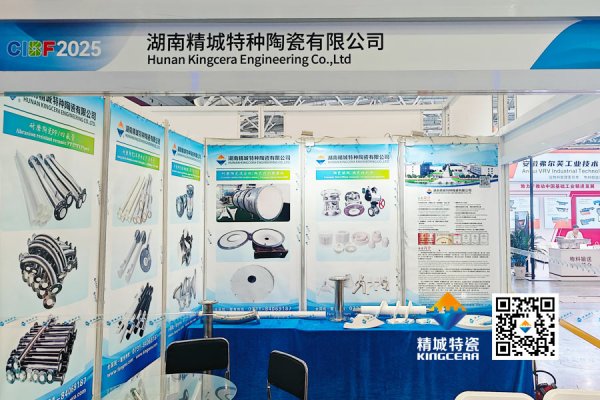

KINGCERA Showcases Innovative Ceramic Solutions at Changsha International Construction Equipment Exhibition 2025

05-21-2025

KINGCERA attended the 2025 Shenzhen Lithium Battery Expo

05-19-2025

Kingcera attend the show of Ceramic Expo 2025 in the U.S.

05-09-2025